Coupling Urine Diverting Flush Toilets with Anaerobic Co-Digestion in the Global South - Modelling Climate Benefits in Kpong, Ghana

In the Global South, urine diverting dry toilets have been successfully tested as feasible tools toincrease sanitation coverage. However, many people desire flush toilets. Some approaches to treatwastewater from flush toilets have been implemented successfully, yet many sanitation projectshave failed because operation and maintenance costs were too high. Biogas production fromwastewater can be seen as a tool that benefits operators directly and tangibly, reducing thelikelihood of sanitation projects to fail due to economic reasons once in operation. However,decentralized treatment systems in the Global South that can cope with larger quantities offlushwater do not provide reliable gas retrieval mechanisms. Fixed-dome digesters (FDDs) canprovide a simple retrieval mechanism without the need for electricity or moving parts, allowing forsustainable gas collection. However, they are not used for treatment of diluted wastes, as this wouldmake them unreasonably large. Urine diverting flush toilets (UDFTs) can save large quantities ofwater due to reduced flushwater consumption for urinations and could therefore enable thecombination of flush toilets with biogas collection.For a specific trade center with a size of 120 person-equivalents in Ghana, the economic andgreenhouse gas (GHG) mitigation benefits of using this combination were compared against astandard anaerobic wastewater treatment approach without biogas collection. It was analyzed howflushwater consumption and co-digestion with food waste affect operational benefits, increasedinvestment costs, and space consumption. This was done by comparing the influences of thedifferent treatment elements used in the two approaches, namely the FDD, Imhoff tank, anaerobicbaffled reactor, urine storage and composting of food waste as an alternative to co-digestion in theFDD. A key underlying assumption was that all water and nutrients would be properly reused.Theoretical calculations were performed using URWARE wastewater data and treatment modellingapproaches that were combined with DEWATS engineering guidelines. An emission modellingapproach was set up to investigate how different flushwater and food waste quantities affectemissions from the compensation tank of the FDD. Additionally, effects of varying LPG and carbonprices as well as effects of leaks and lack of flaring were shown and it was investigated how resultscould be translated to differing user populations.It was found that about 700 USD can be saved per year but additional initial investment cost wouldbe as large as 13,600 USD. Still, 32% of initial investment costs were attributed to urine storage,which may not be needed in some cases. GHG emissions from construction would amortize alreadyafter 1.7 years and 200 tCO2-eq could be mitigated after 20 years of operation. Adjustment with acarbon price of 100 USD tCO2-eq-1 would allow for economic amortization after 8.6 years, resultingin economic savings of 20,400 USD after 20 years of operation. Food waste dosage did not affectthis result significantly, showing that co-digestion is not needed if this carbon price would be ineffect. In conclusion, UDFTs are a powerful tool to mitigate GHG emissions and ensure continuedtreatment system operation in the Global South, however technology diffusion will require adequatefunding mechanisms that can cope with the increased investment costs.

Show LessCoupling Urine Diverting Flush Toilets with Anaerobic Co-Digestion in the Global South Modelling Climate Benefits in Kpong, Ghana |

|---|

Bachelor’s Thesis In partial fulfillment of the academic requirements for the degree B.Sc. Environmental Engineering Chair of Urban Water Systems Engineering School of Engineering and Design Technical University Munich Supervisors M.Sc. Mohammad Bardi Chair of Urban Water Systems Engineering PD Dr.-Ing. Konrad Koch Chair of Urban Water Systems Engineering Submitted by Felix Giglberger Date of submission 2022-06-12 |

Abstract

In the Global South, urine diverting dry toilets have been successfully tested as feasible tools to increase sanitation coverage. However, many people desire flush toilets. Some approaches to treat wastewater from flush toilets have been implemented successfully, yet many sanitation projects have failed because operation and maintenance costs were too high. Biogas production from wastewater can be seen as a tool that benefits operators directly and tangibly, reducing the likelihood of sanitation projects to fail due to economic reasons once in operation. However, decentralized treatment systems in the Global South that can cope with larger quantities of flushwater do not provide reliable gas retrieval mechanisms. Fixed-dome digesters (FDDs) can provide a simple retrieval mechanism without the need for electricity or moving parts, allowing for sustainable gas collection. However, they are not used for treatment of diluted wastes, as this would make them unreasonably large. Urine diverting flush toilets (UDFTs) can save large quantities of water due to reduced flushwater consumption for urinations and could therefore enable the combination of flush toilets with biogas collection.

For a specific trade center with a size of 120 person-equivalents in Ghana, the economic and greenhouse gas (GHG) mitigation benefits of using this combination were compared against a standard anaerobic wastewater treatment approach without biogas collection. It was analyzed how flushwater consumption and co-digestion with food waste affect operational benefits, increased investment costs, and space consumption. This was done by comparing the influences of the different treatment elements used in the two approaches, namely the FDD, Imhoff tank, anaerobic baffled reactor, urine storage and composting of food waste as an alternative to co-digestion in the FDD. A key underlying assumption was that all water and nutrients would be properly reused. Theoretical calculations were performed using URWARE wastewater data and treatment modelling approaches that were combined with DEWATS engineering guidelines. An emission modelling approach was set up to investigate how different flushwater and food waste quantities affect emissions from the compensation tank of the FDD. Additionally, effects of varying LPG and carbon prices as well as effects of leaks and lack of flaring were shown and it was investigated how results could be translated to differing user populations.

It was found that about 700 USD can be saved per year but additional initial investment cost would be as large as 13,600 USD. Still, 32% of initial investment costs were attributed to urine storage, which may not be needed in some cases. GHG emissions from construction would amortize already after 1.7 years and 200 tCO2-eq could be mitigated after 20 years of operation. Adjustment with a carbon price of 100 USD tCO2-eq-1 would allow for economic amortization after 8.6 years, resulting in economic savings of 20,400 USD after 20 years of operation. Food waste dosage did not affect this result significantly, showing that co-digestion is not needed if this carbon price would be in effect. In conclusion, UDFTs are a powerful tool to mitigate GHG emissions and ensure continued treatment system operation in the Global South, however technology diffusion will require adequate funding mechanisms that can cope with the increased investment costs.

Table of Content

1.1 The Sanitation Problem in the Global South 1

1.1.2 The issue with flush toilets 2

1.2.1 The Ghanaian background 3

1.2.2 Economic incentives and environmental framework 3

2.1 Urine diverting flush toilets 5

2.2.2 Fully mixed fixed-dome digester 6

2.2.3 Imhoff tank and anaerobic baffled reactor 8

4.2 Substrate characterization 13

4.3 Digestion and Emission Modelling 14

4.6 Anaerobic baffled reactor 19

5.1 Gas production and emission 23

6.3 Applicability in Ghana and the Global South 29

8 References Error! Bookmark not defined.

Appendix A – Design drawings vii

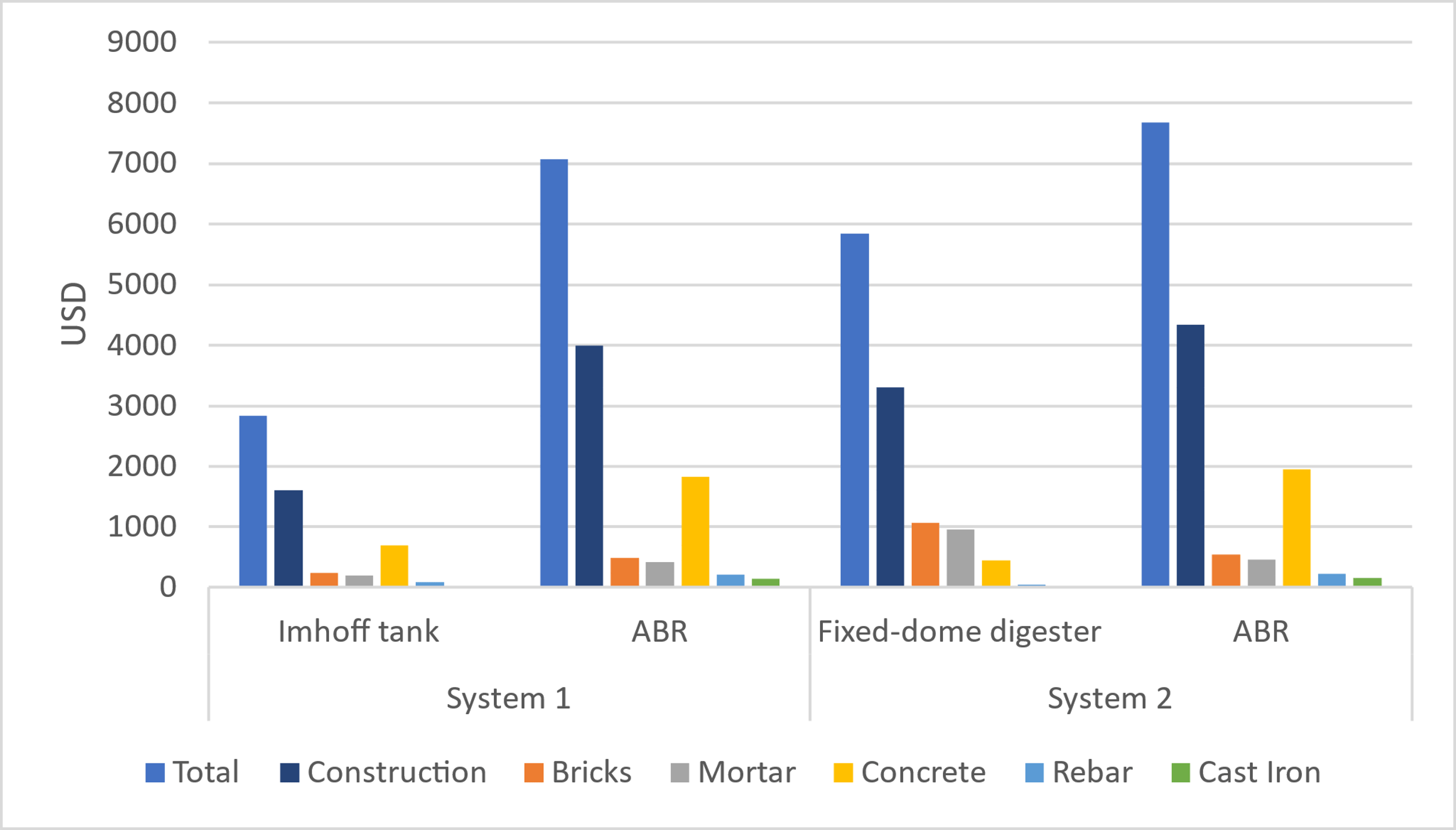

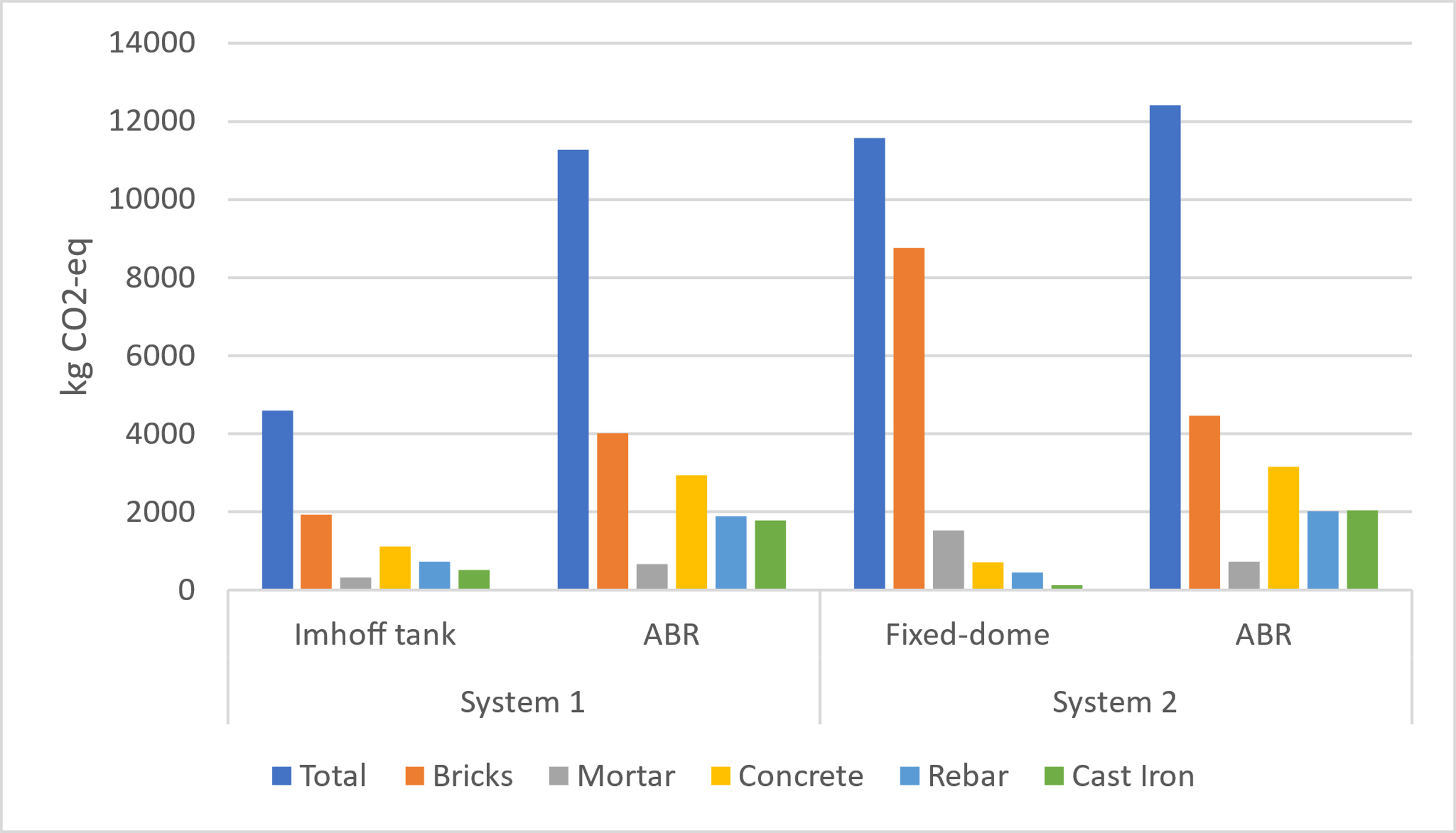

Appendix B – Contributions of different construction materials viii

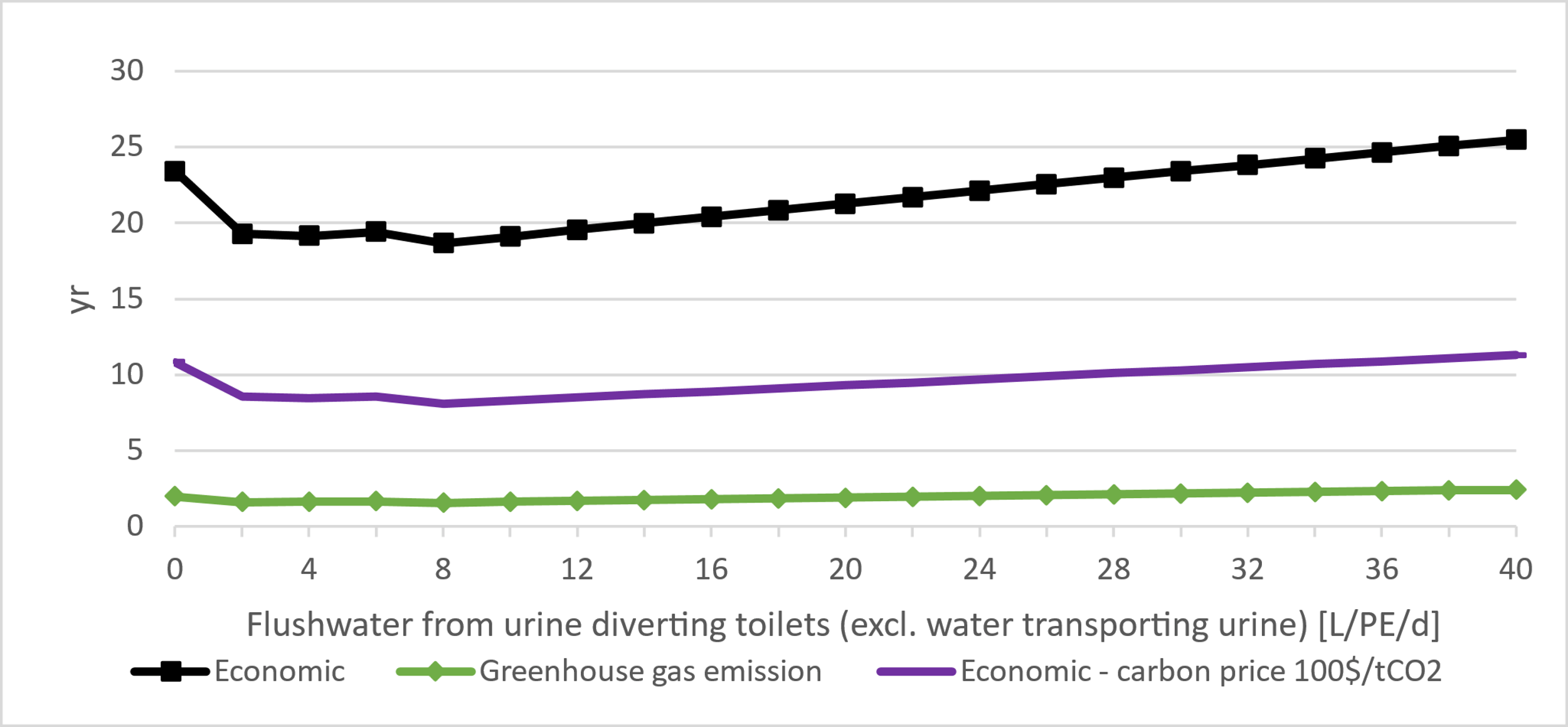

Appendix C.1 – Flushwater effects ix

Appendix C.2 – Effects of food waste dosage xi

Appendix C.3 – Effects of gas losses xiii

Appendix C.4 – Effects of general system size xiv

List of Figures

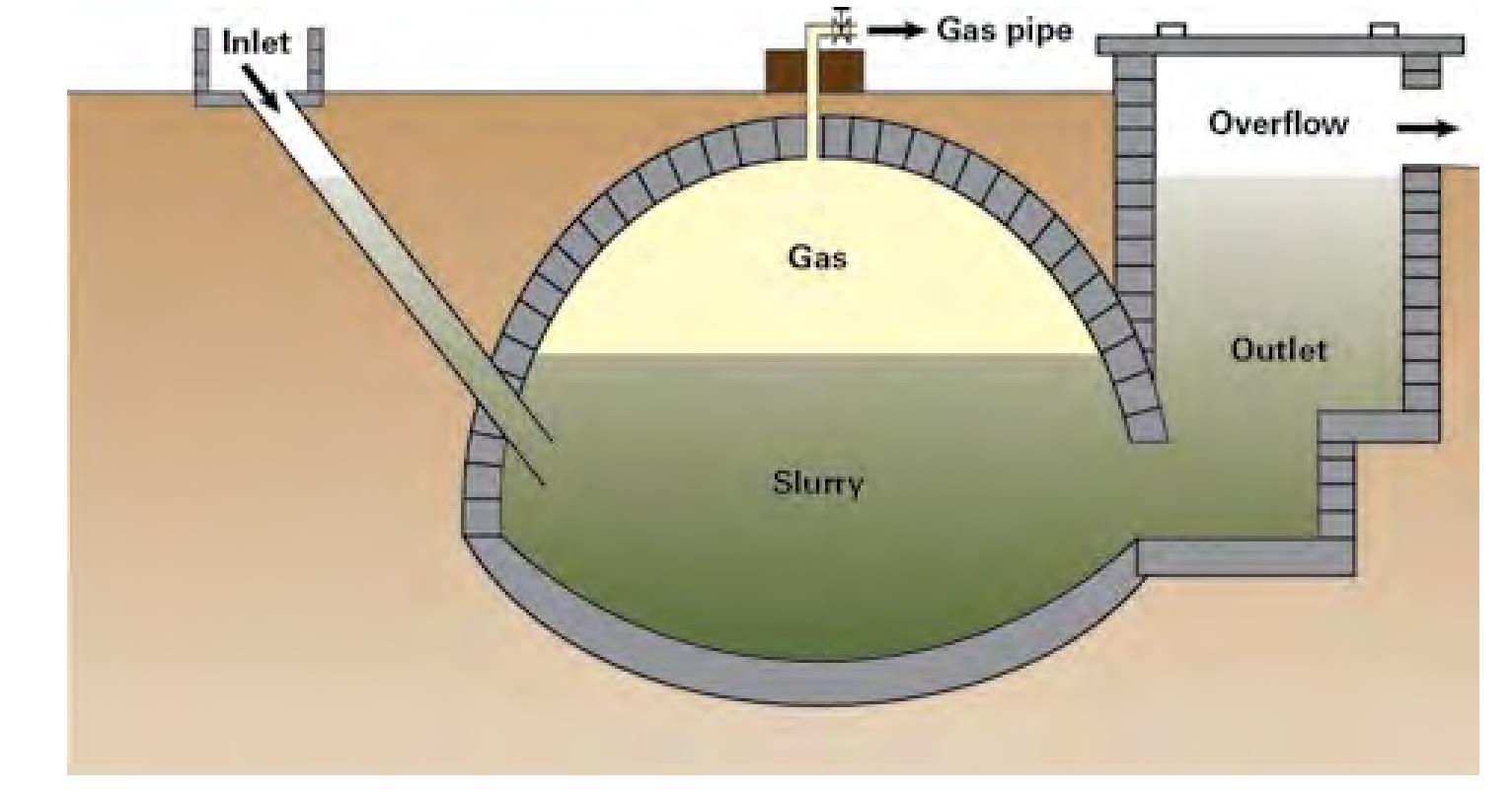

Figure 1: Scheme of fixed-dome digester (Vögeli et. al. 2014) 7

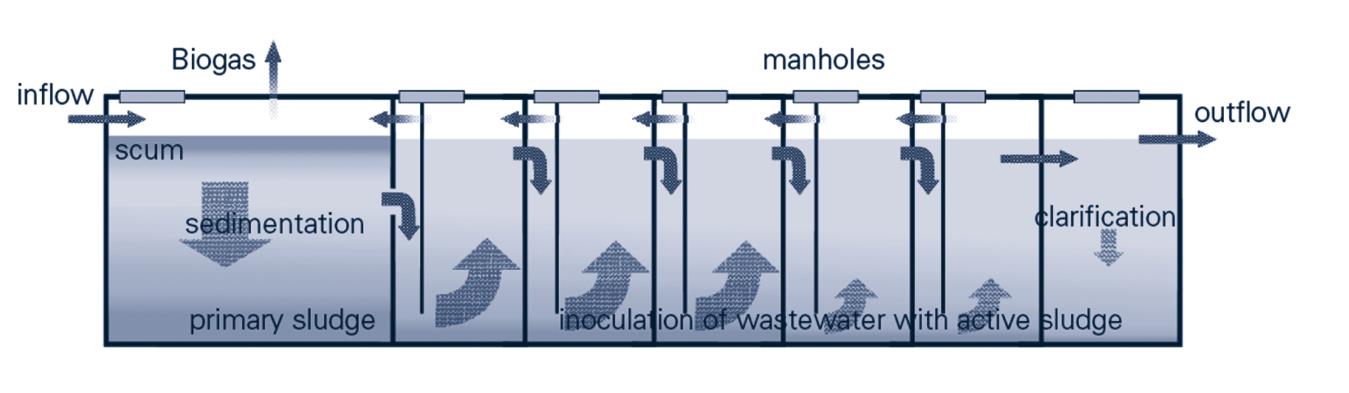

Figure 2: Imhoff tank design - (Gutterer et al. 2009) 8

Figure 3: Design of an anaerobic baffled reactor - (Gutterer et al. 2009) 8

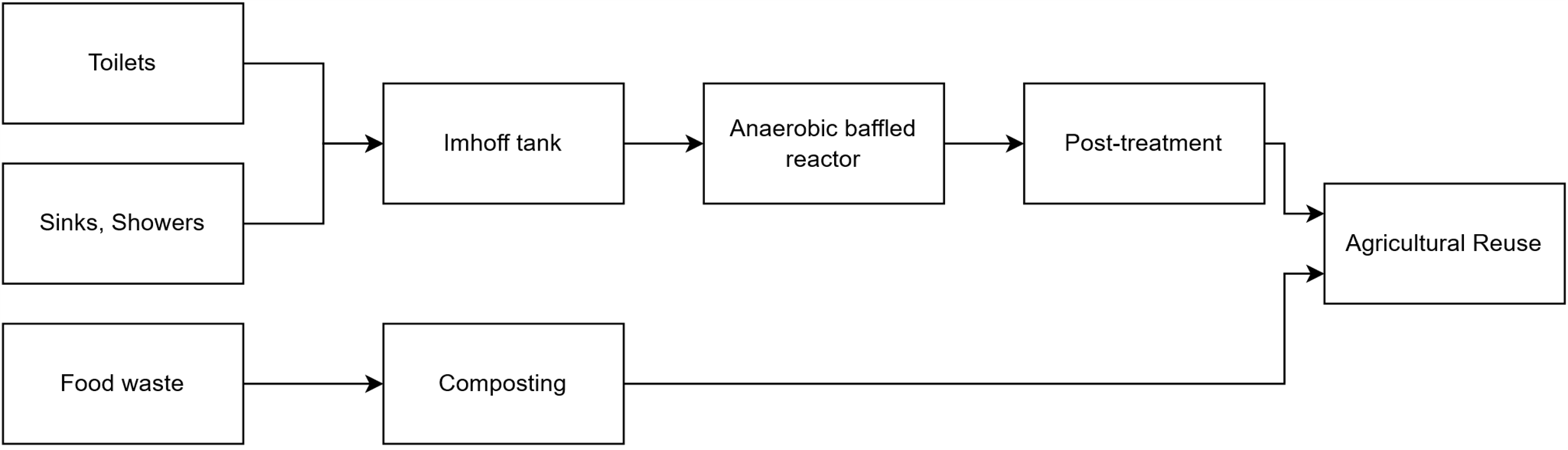

Figure 4: System 1 configuration 10

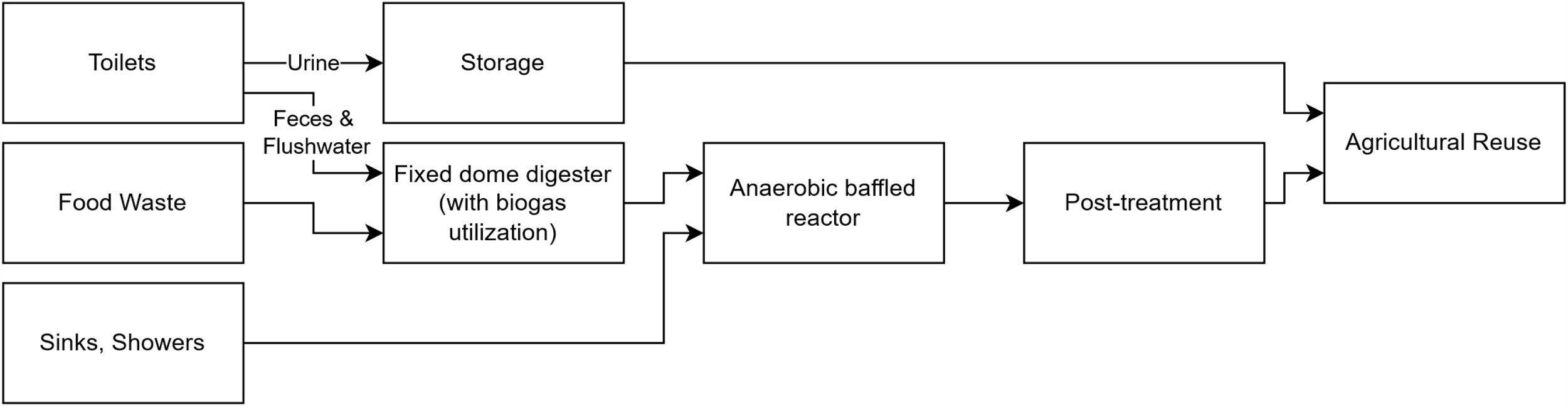

Figure 5: System 2 configuration 10

Figure 7: CH4 emissions compared between system 2 components 23

Figure 8: Comparison of systems regarding CH4 emissions 24

Figure 9: Effects of flushwater consumption on amortization time of system 2 24

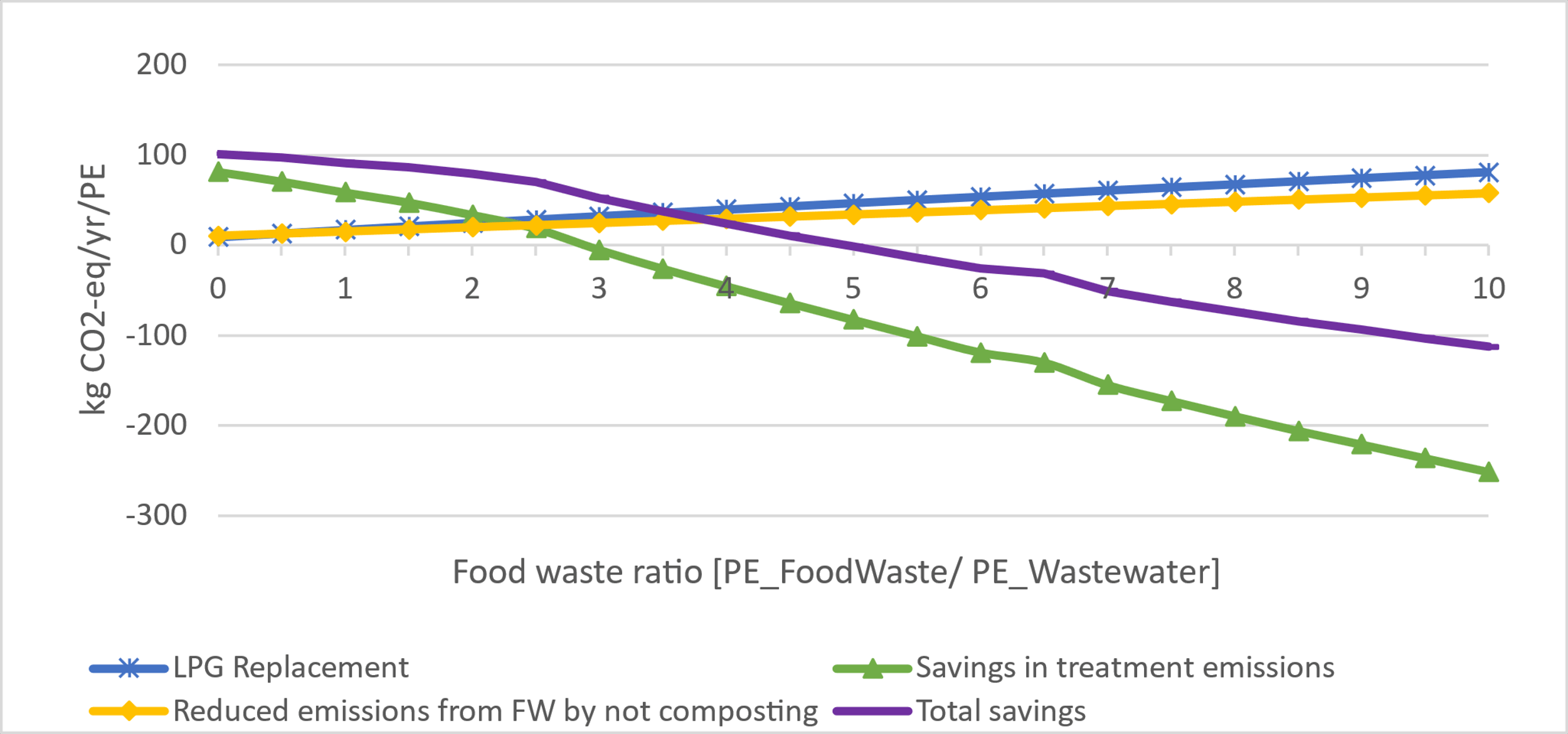

Figure 11: Effects of food waste ratio on amortization time of system 2 compared to system 1 26

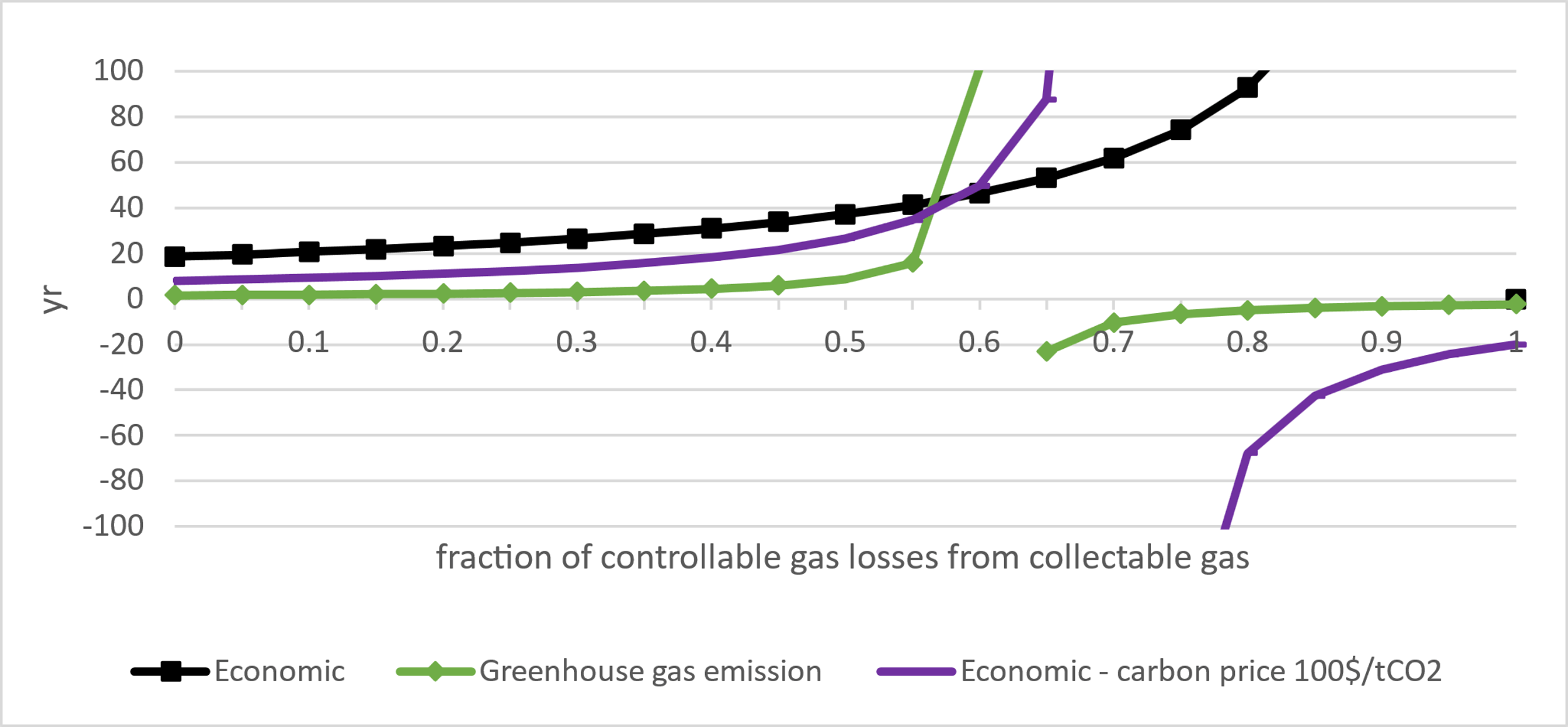

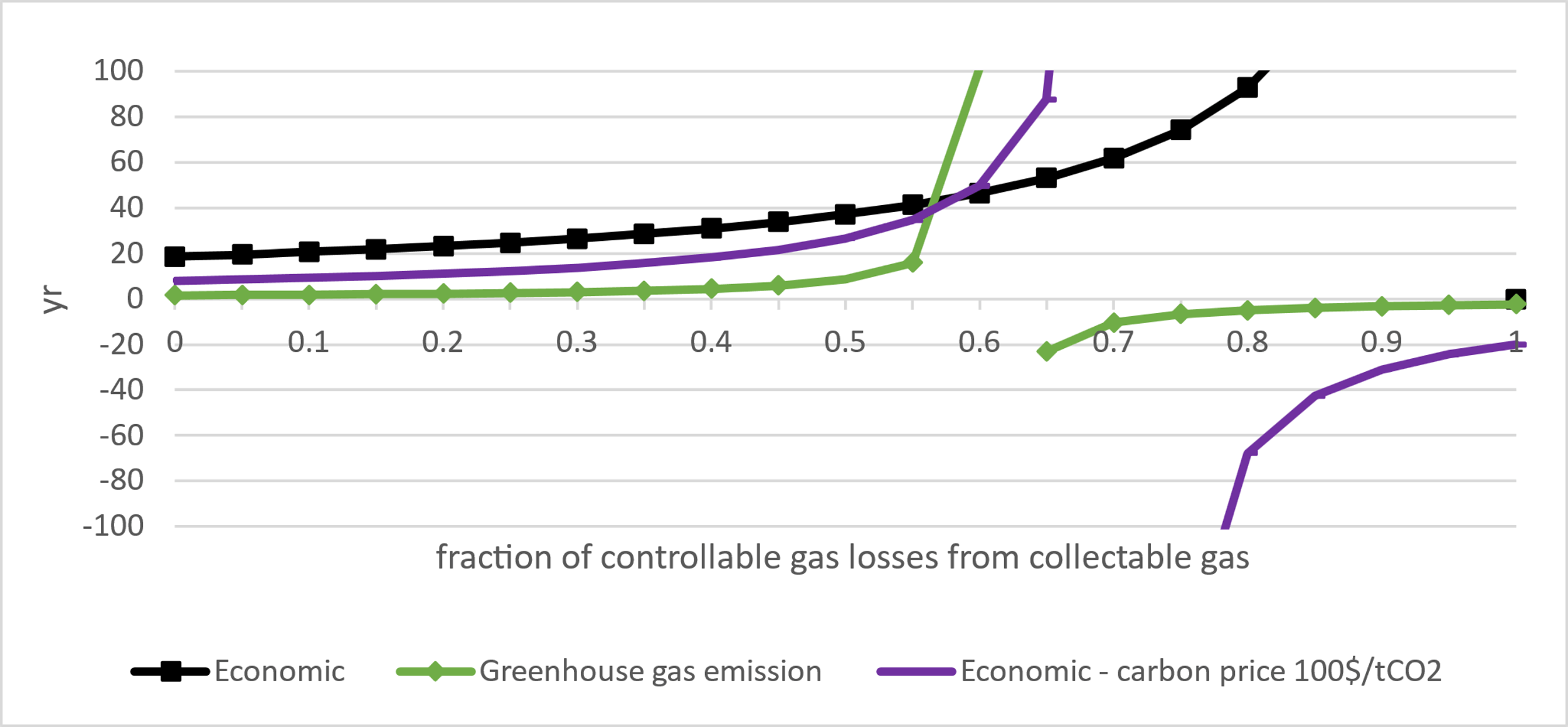

Figure 12: Effect of external gas losses on amortization time of system 2 compared to system 1 26

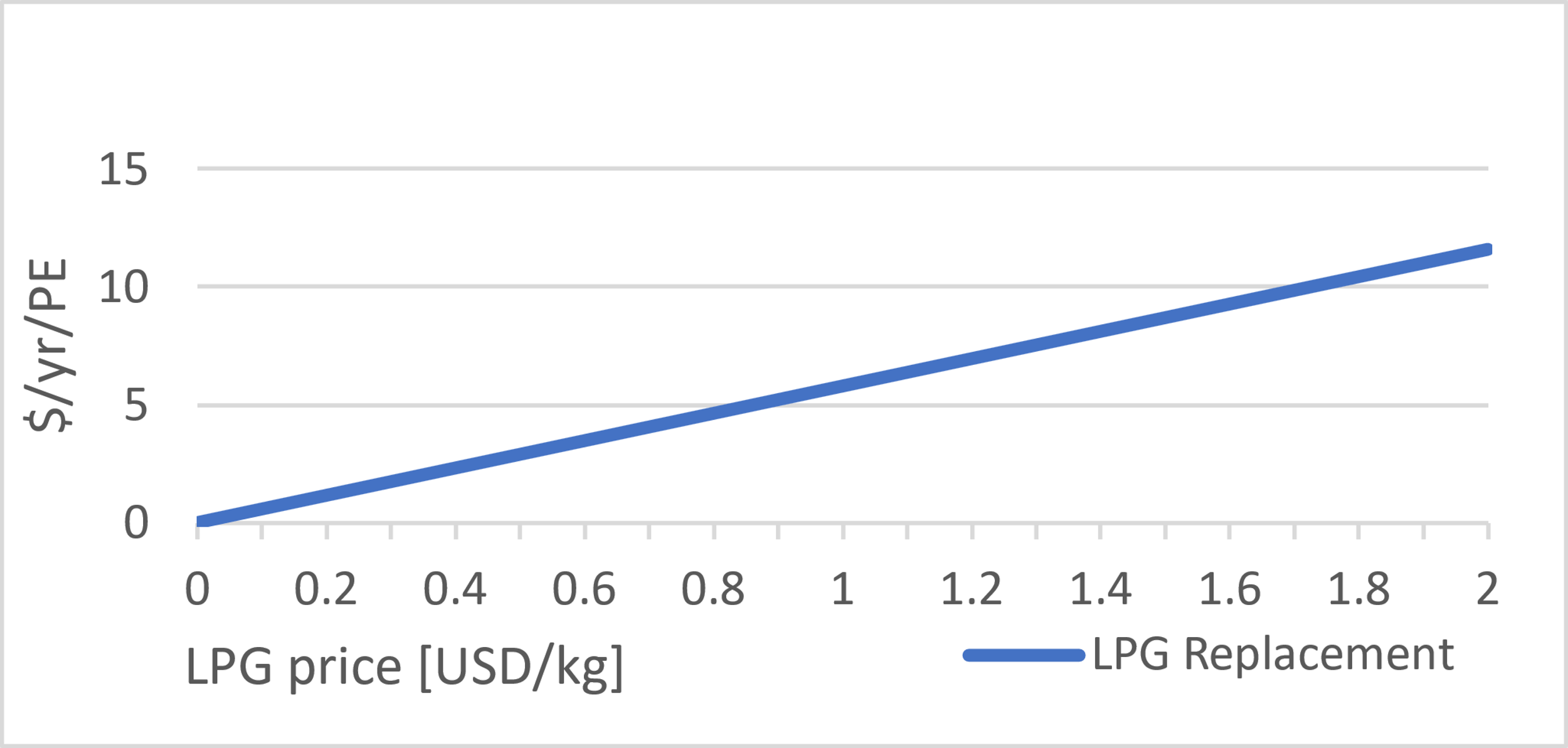

Figure 13: Effect of LPG price on Economic savings 27

Figure 14: Effects of LPG Price on amortization time of system 2 over system 1 27

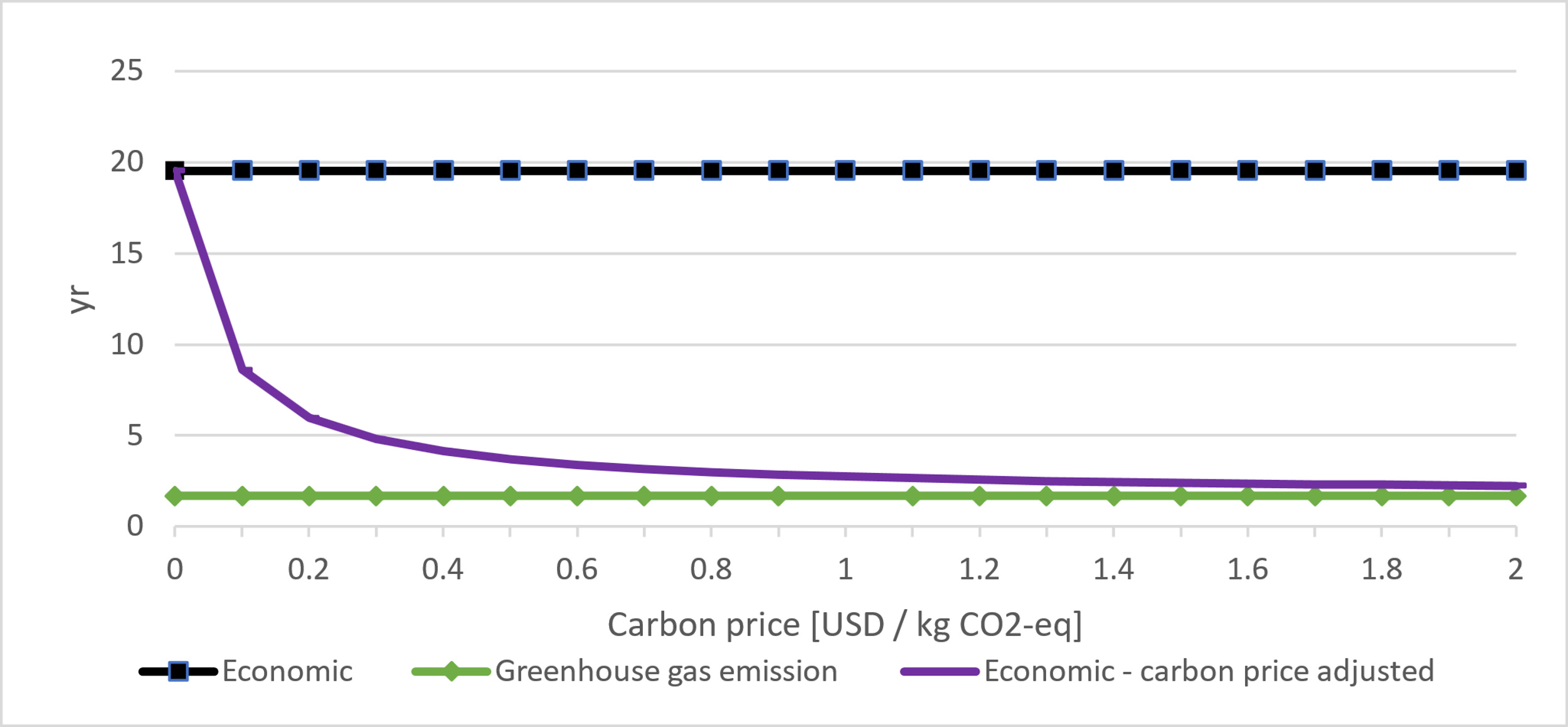

Figure 15: Effect of carbon pricing on amortization time of system 2 over system 1 27

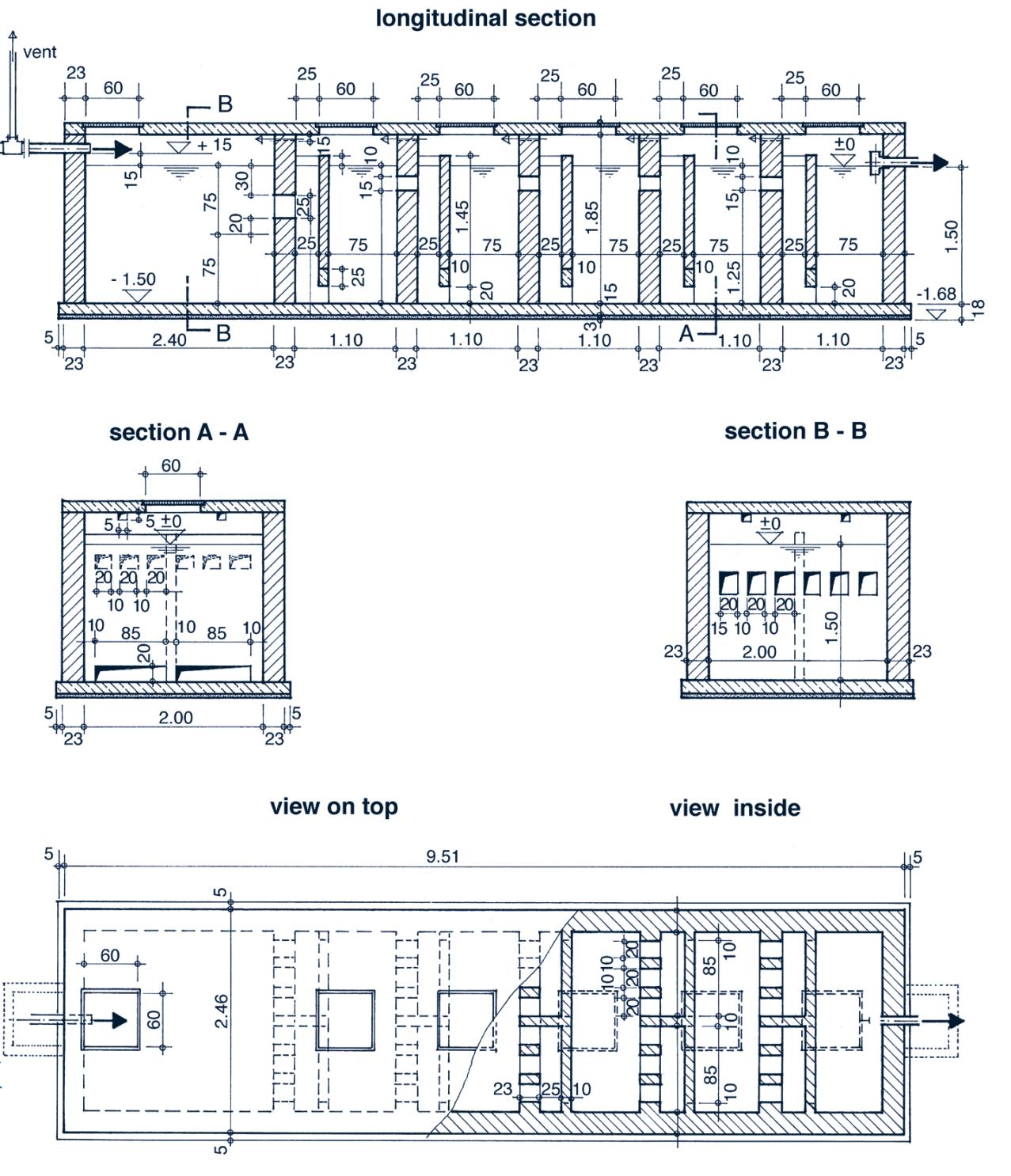

Figure 16: Imhoff tank design figures (DEWATS Chapter 9 Technical Components 2009) vii

Figure 17: Anaerobic baffled reactor design figures (DEWATS Chapter 9 Technical Components 2009) vii

List of Tables

Table 1: General operational assumptions 11

Table 2: Building material properties 11

Table 4: Physical constants regarding LPG substitution 15

Table 5: Fixed-dome parameters 16

Table 6: Calculated parameters for fixed-dome modelling 17

Table 7: Imhoff tank design parameters 18

Table 8: Anaerobic baffled reactor design parameters 19

Table 9: Urine treatment parameters 21

Table 10: Assumptions regarding composting 22

Abbreviations

ABR – Anaerobic Baffled reactor

ADM1 – Anaerobic Digestion Model 1

BOD – Biochemical oxygen demand

BORDA – Bremen Overseas Research and Development Association

bpCOD – biodegradable particulate COD

bsCOD – biodegradable soluble COD

COD – Chemical Oxygen Demand

DEWATS – Decentralized wastewater treatment systems

FDD – Fixed-dome digester

GHG – Greenhouse gas

nbpCOD – non biodegradable particulate COD

nbsCOD – non biodegradable soluble COD

O&M – Operation and maintenance

PE – Person-equivalents

SDFT – Standard dual-flush toilet

UDDT – Urine diverting dry toilet

UDFT – Urine diverting flush toilet

URWARE – Urban water research model

Introduction

The Sanitation Problem in the Global South

To achieve sustainable development goal number 6 aiming for full sanitation coverage by 2030, the rate at which sanitation coverage is increasing will need to quadruple. Half of the world’s population use sanitation services that leave human waste untreated, threatening human and environmental health as well as economic development. 26% do not have basic access to sanitation facilities, causing 830,000 deaths annually. In an environmental domain, inadequate management of human excreta is associated with pollution of ecosystems and contributes significantly to global greenhouse gas emissions and resource depletion. (UNICEF and WHO 2020)

Cost of sanitation

The economic cost of decreased productivity from death and disease in Sub-Saharan Africa has been estimated to be on average 3.2% of its Gross Domestic Product, which is why estimates of economic return generated from investments in the sanitation sector are generally beyond five times the investment. However, with an estimated annual budget of 105 billion US-dollars (USD) needed to reach universal sanitation by 2030, many countries have complained about a lack of possibilities for financing their goals. Yet, sanitation as a sector has been largely underprioritized and suffers from various institutional failures. This includes financial mismanagement, with operation and maintenance costs often not included in budgets. (UNICEF and WHO 2020).

Many governments focus on keeping investment costs to a minimum, but this can easily result in failures. In Ghana, many people have abandoned pit latrines co-financed by the government, as emptying would cost them more than paying for privately owned public toilets, with some reverting to open defecation (Appiah-Effah et al. 2014). Providing people with sanitation does make economic sense, but the return generated is largely intangible to the individual. With approaches that can generate tangible profits from wastewater treatment, donors and lenders could be less reluctant to provide the needed funding and projects would be less likely to fail if operation & maintenance costs are lower than the tangible benefits generated at the user level. However, such approaches will necessarily facilitate higher investment costs. This thesis aims to investigate one such approach and attempts to quantify the relevant economic parameters in order to enable decision-making on the feasibility of adoption.

The proliferation of cheap sanitation technologies also has an environmental cost. Shaw et al. (2021) showed that achieving the sanitation targets of the United Nation’s Sustainable Development Goals will increase greenhouse gas emissions by 7 to 68 TgCO2-eq yr-1, which can amount to 0.2% of global anthropogenic emissions. This was mainly attributed to septic tanks and pit latrines, as these systems are anaerobic and subsequently emit more methane than natural decomposition. Capturing and burning the methane would therefore significantly reduce emissions caused by increasing sanitation coverage.

The issue with flush toilets

Cheap sanitation technologies may face problems of social acceptance. Narain (2002) concluded in grey literature that with increasing economic development people would discard cost-effective technology solutions and increasingly use flush toilets that convey wastewater without treatment, even if that would lead to more environmental problems. Flush toilets are seen as desirable ambition (J Behrendt et al. 2006, p. 6), while dry toilets are often seen as an inferior and unjust solution for the poor (Reynaud 2014; Larsen et al. 2021). However, flush toilets lead to surface water pollution and losses in biodiversity while also increasing reliance on mineral fertilizers (Larsen et al. 2021). They facilitate water stress (Larsen et al. 2013) and the high energy demand of treating water to drinking water quality for toilet flushing significantly contributes to the environmental impact of sanitation, even in the Global South (Wissing 2020). As the demand for flush toilets will grow, strategies need to be found to mitigate the negative impacts of flush toilets, so that the environmental problems caused in the Global North are not repeated in the same degree or worse in the Global South. Many of the negative impacts could be largely reduced by water reuse, however treatment technologies will need to adapt and still prevail within socioeconomic conditions. This thesis aims to quantify the economic and ecological differences of two treatment approaches towards diluted wastewater using established technologies for the Global South and to explore their sensitivity to the amount of flushwater in order to quantify effects of water-saving.

The case study

There are many input parameters needed for the analysis performed that can fluctuate and are subject to regional differences. In order to avoid complexity, some parameters will be fixed to standard values only valid for the specific case to be introduced. However, some of the parameters will be sensitized to enable decision making for similar cases.

The investigation focusses on a trade center near Kpong in the Eastern region of Ghana. It is expected to host 120 person-equivalents (PE) of workers and visitors. The center is built and operated by a NGO that has the goals of providing good working conditions for underprivileged women and revitalizing Ghana’s textile industry.

The trade center produces multiple sources of wastewater, but this thesis will not include any wastewater produced by the manufacturing processes. This decision has been made as (i) the wastewater remains poorly characterized as laboratories in Ghana lack capabilities to analyze parameters needed in the model used in this thesis, (ii) laboratories in Ghana have not always managed to provide realistic values for some analyzed parameters, (iii) industrial wastewater will likely be treated separately as it may not be treatable to satisfactory levels for agricultural reuse using local technologies, (iv) models used in this thesis have only been validated with municipal sources and (v) better comparability to other projects can be achieved as complexity is reduced.

The Ghanaian background

Ghana largely suffers from the same problems as the Global South in general. Set targets of the Millenium Development Goals have largely not been met by wide margins (Appiah-Effah et al. 2019). A survey conducted by the Ghana Statistical Survey (2018) found that only 21% of the population uses basic sanitation facilities, with next to none being safely managed. It established that pit latrines are the main sanitation technology, which is used by 40% of the population. 2% of the population has access to sewers and 19% have their excreta removed for treatment elsewhere (Ghana Statistical Service 2018). However, fecal sludge treatment facilities and conventional sewer-based treatment systems have largely failed in Ghana, with decentral methods of treatment being more wide-spread (Appiah-Effah et al. 2014). One example used in Ghana is the Biofil-toilet treatment system, yet it has been shown that it is not sufficient as a standalone technology to achieve acceptable effluent levels (Kuwornu 2014). Biogas technology has been applied mainly at the institutional level and mainly to prevent problems from excessive firewood usage like air pollution and deforestation (Arthur et al. 2011, p. 1514). Multiple companies have realized its financial benefit and treat fecal sludge collected by sewage trucks, also sometimes with wastewater reuse of the effluent to mitigate reliance on chemical fertilizers as predicted by Arthur et al. (2011, p. 1516). Co-digestion with various industrial wastes is also performed, however post-treatment infrastructure is still lacking at two observed treatment sites.

Problems of the slow progress in the sanitation sector have been associated with institutional failures like poor working conditions, understaffing of technical personnel and unclear guidelines, as well as social provisions against fecal management. Financially, sanitation is not prioritized compared to drinking water provision. Economic losses due to poor sanitation were found to be higher than what was invested. Donor funding is dwindling and the government now increasingly relies on private sector participation and tariffs. (Appiah-Effah et al. 2019, pp. 406–409)

Economic incentives and environmental framework

The center and wastewater system are built with donor funds. Although decreasing, donor grants still make up 42% of non-household sanitation investments in the Global South (UNICEF and WHO 2020). Therefore, an incentive is given to maximize benefits of the wastewater treatment systems, even though investment costs may be higher. Environmental benefits of non-standard wastewater treatment facilities could also provide economic advantages in the form of corporate social responsibility marketing, which may be applicable in this case as target markets are mainly in the developed world.

The lack of a sewer system, drainage canals, and nearby waterways, as well as limited space availability and poor soil conductivity, facilitate the need for water reuse on production crops planted on the compound. Fertigation, a combination of irrigation and fertilization, is limited by the quantities of crops harvested. To avoid overfertilization without the need for denitrification, either the nutrients of urine need to be extracted separately and applied elsewhere, the treatment sludge cannot be reused or no food waste can be added to the treatment process for enhanced biogas production. Therefore, UDFTs also present the opportunity to gain a concentrated fertilizer product that could be sold to surrounding farmers.

Social factors

Support for wastewater reuse and biogas production is high with only three of 53 sampled people expected to work at facility having reservations against use of biogas and two against wastewater reuse. Four workers were undecided in the two respective cases. The facility is planned to have 200 workers. In 83% of worker households food waste was not utilized. In total, workers were willing to bring on average 1.96 PE worth of food waste from their homes, counting children as 0.5 PE. It is to be investigated how this would influence the choice of treatment system provided. Due to experience with previously used Biofil-toilets, workers can be trusted to use toilets correctly and bins for disposing toilet paper can be used. Anal cleansing with water is not practiced.

Theoretical Background

Urine diverting flush toilets

Urine diverting flush toilets (UDFTs) generally collect urine undiluted or diluted with little flushwater separately from feces, which are flushed as in a conventional toilet. Various toilet designs have been tested with varying degrees of separation, dilution and success (González-Salgado 2017). However, many institutional challenges and problems regarding social acceptance of toilet design have been overcome in over three decades of research, which makes large scale marketing possible (Larsen et al. 2021). So far, UDFTs have largely been used only in sewered areas in Europe, while the Global South has only seen proliferation of urine diverting dry toilets (Larsen et al. 2021).

The main argument provided for use of UDFTs in literature is resource recovery, as urine contains a large amount of excreted nutrients in a concentrated form. This makes them more easily extractable and reusable (Peter-Fröhlich et al. 2007) and reduces nitrogen pollution, mitigating ecological problems like eutrophication (Larsen et al. 2021, p. 1165). It moreover replaces mineral fertilizers without compromises in effectiveness (Peter-Fröhlich et al. 2007; Münch and Winker 2011). This alleviates various environmental, geopolitical and socioeconomic burdens associated with mineral fertilizers (Münch et al. 2009; Larsen et al. 2013).

Another major advantage of UDFTs that is not as often mentioned is their ability to save large amounts of water, up to 80% compared to conventional toilets (González-Salgado 2017). This results from their ability to use no or much less water for urine-only flushes, which are about 5.5 times more common than flushes with feces (Rose et al. 2015). It especially holds true when toilet paper used after urination is disposed of separately and does not need to be flushed (Münch and Winker 2011). The benefits of water saving are generally considered to be hydrological, environmental, associated with the cost of treating toilet water to drinking water standards and water-price-related (Münch and Winker 2011). However, treatment infrastructure costs and emissions are also affected, which will be further investigated in this thesis. While back-end applications for treating urine have been and are further developed, less attention has so far been paid towards application for treatment of diluted feces (Larsen et al. 2021). In a notable exception, Reynaert et al. (2020) have recently developed a toilet system that can independently treat urine, feces and greywater while recovering nutrients and recycling water internally. For treatment of diluted feces, hydrothermal oxidation and an aerated bioreactor have been suggested. It may be suited for the Global South and can solve the problems associated with flush toilets, but chemical and electricity consumption as well as complexity regarding maintenance problems could hamper technology diffusion.

Lastly, exclusion of urine from the main treatment can lead to more favorable conditions for biogas generation, as it shifts the carbon to nitrogen ratio in a favorable direction (Dahlmann 2009).

While resource recovery will be a major argument for UDFTs in the Global North, water saving and its effects on biogas generation further explained in the next section could be the prevailing drivers for proliferation of UDFTs in the Global South. This thesis investigates how influential these respective factors are, so that feasibility of spreading UDFTs in the Global South can be assessed.

The DEWATS approach

Decentralized Wastewater Treatment Systems (DEWATS) is an approach to wastewater treatment specialized for the Global South that was pioneered by the German NGO Bremen Overseas Research and Development Association (BORDA). It is a modular concept that encompasses multiple technologies, which need to be chosen according to local circumstances. It constitutes low-technology, self-manageable combinations of space-efficient, independent technology for small to medium sized communities. The DEWATS components consist of a pretreatment step, which is usually a septic tank or Imhoff tank, followed by an anaerobic baffled reactor (ABR) as a main stage. Post-treatment is usually carried out by ponds, wetlands, or both. Its systems have increasingly gained recognition as easy to operate with low operating costs. (Wissing 2020; Gutterer et al. 2009)

Although DEWATS is a general concept, BORDA has outlined and tested specific approaches for engineering the different system components in a standardized way, which makes comparability between different systems within the scope of this thesis possible. This work refers specifically to the approaches outlined by BORDA (Gutterer et al. 2009).

Anaerobic digestion

The pretreatment units and main stage of the DEWATS system are anaerobic because it can treat high strength wastes without the need for expensive and maintenance-prone aeration equipment (Gutterer et al. 2009). Anaerobic digestion is a natural process that takes place in areas rich in organic substrate where free oxygen is not available or has already been depleted (Murphy and Thamsiriroj 2013). Although utilized since the mid-1800s, with respect to wastewater treatment, it has gained popularity in the last decades mainly due to its ability to produce biogas, which can be used as energy (Kythreotou et al. 2014, p. 701).

There are two basic approaches used with regards to anaerobic treatment. In the first approach, biomass is suspended. The waste stream and degrading biomass have the same retention time in the reactor, meaning the hydraulic retention time (HRT) and the solid retention time (SRT) are equal. In the second approach, biomass is sessile, meaning that SRT is significantly lower than HRT, which allows for smaller treatment elements. (Larsen et al. 2013, p. 326).

Fully mixed fixed-dome digester

The fully mixed digester functions as a continually stirred tank

reactor with suspended biomass. Mixing is generally provided by the

biogas generated from anaerobic digestion (Larsen et al. 2013, p. 326).

There exist different types of fully mixed digesters, but in the Global

South mainly fixed-dome digesters (FDDs) and floating-drum digesters are

used. FDDs comprise of a main digestion  cylinder, a rigid gas holder

above and a compensation tank. Gas is retrieved batch-wise, while liquid

continuously flows into the digester. As gas is produced, liquid is

pressed into the compensation tank. Upon retrieval, the compensation

tank empties out and provides the necessary pressure, so that neither

energy nor moving parts are required. This makes the system durable and

fit for application in the Global South. Figure 1 shows the design of a

typical FDD. (Vögeli et al. 2014)

cylinder, a rigid gas holder

above and a compensation tank. Gas is retrieved batch-wise, while liquid

continuously flows into the digester. As gas is produced, liquid is

pressed into the compensation tank. Upon retrieval, the compensation

tank empties out and provides the necessary pressure, so that neither

energy nor moving parts are required. This makes the system durable and

fit for application in the Global South. Figure 1 shows the design of a

typical FDD. (Vögeli et al. 2014)

Biogas collection is beneficial because it can replace other fuel sources and their associated environmental and social impacts, which can lead to a reduction in greenhouse gas emissions, women empowerment, health benefits, reforestation, and a reduction in dependencies at the personal and national level (Arthur et al. 2011).

Moreover, collection and subsequent combustion converts the collected methane to carbon dioxide. This has environmental benefits as methane has a 100-year Global Warming Potential 28 times greater than carbon dioxide (Stocker 2014), so if the waste would have otherwise partially undergone aerobic digestion and methane is not collected and burned, biogas production contributes to Global Warming. Carbon dioxide emissions from anaerobic digestion of wastewater do not contribute to Global Warming, as this process only returns what has previously been extracted from the atmosphere. (Vögeli et al. 2014)

The amount of gas collected can be increased with the co-digestion of other wastes, for example food waste. Combining human feces with food waste has been shown increase process stability and gas production by improvement of the buffering capacity, dilution of inhibitory compounds, and facilitation of synergistic effects by providing a more favorable carbon to nitrogen ratio. (Kim et al. 2019)

The addition of food waste also concentrates the digestate, which can justify the use of suspended biomass systems like the fixed dome digester. However, this will necessarily also facilitate more emissions of non-captured methane that will not be converted to carbon dioxide afterwards. Another disadvantage is the large HRT needed, which makes fixed dome digesters big and expensive if substrate is diluted with flushwater (J Behrendt et al. 2006). Although these cause-effect relationships have been known for decades, little emphasis has been placed on their quantification beyond individual case studies (Mathieu Dumont et al. 2013, p. 263). While greenhouse gas emissions from mainly agricultural plants in the Global North have been extensively studied (Paolini et al. 2018), various emission aspects of the digestion process and digestate application are not translatable to treatment infrastructure in the Global South, where emission estimates vary significantly (Bruun et al. 2014).

Imhoff tank and anaerobic baffled reactor

The Imhoff tank is a standard solution in the DEWATS approach that works with sessile biomass, meaning SRT and HRT are decoupled. This allows for a compact design because dilution does not have major effects on the treatment system size. It is used for pretreatment and tries to minimize odors by phase separation. The anaerobic baffled reactor is the main element of DEWATS. It consists of a settler and usually four to six upflow chambers. It also operates with sessile biomass. It can effectively reduce organic matter content without electricity, odors or large footprint. Figure 2 and 3 show general designs. (Gutterer et al. 2009)

Biogas is produced in both systems but not collected as the simple designs would have to cope with leakages and no simple collection mechanism can be used for developing countries due to the dilution and minimal gas production of typically fed substrate (Wissing 2020).

Research questions

Based on the literature review, multiple research gaps have been identified. Effects of UDFTs on treatment infrastructure for diluted feces have not been sufficiently studied, especially for treatment technology of the Global South. Economic and environmental effects of dilution rates on waste treatment in FDDs were only studied on a case-by-case basis for small systems and no theoretical generalization approach was found that could quantify how these effects differ by changes in substrate composition, dilution of the substrate and general size of the system.

According to problems identified in Introduction and Research Gaps the following research questions were formulated:

What are the most significant changes in treatment structure, the initial investments required and operational benefits due to UDFT introduction in the Global South?

How are they quantified within the project-framework?

How do they differ in their economic, environmental and spatial impact?

How important is the coupling of food waste co-digestion to UDFTs to ensure their applicability?

How do greenhouse gas emissions in fixed dome digesters change with the respective degree of dilution and co-digestion?

Could UDFTs be viable option for the Global South in general? How sensitive are the results to differing input parameters?

The final objective of this thesis is to provide data called for by UNICEF and WHO (2020) that can inform decisionmakers to optimally select treatment systems and therefore tackle the current and future issues of sanitation in the Global South.

Methodology

Two treatment scenarios were compared regarding their differences in upfront investment and operational benefits in an economic, environmental and spatial domain. This was done based on the combination of the URWARE model (Jeppsson et al. 2005), DEWATS dimensioning guidelines (Gutterer et al. 2009) and a scalable model of FDD dimensioning and emission modelling. Microsoft Excel was used for modelling of the anaerobic digestion process in the different reactors and for sensitivity analysis regarding key parameters affecting the economic and environmental differences investigated.

In the following, the treatment approach outlined in Figure 4 referred as System 1 is a standard DEWATS approach combined with composting as a treatment for food waste. It serves as a baseline for comparison.

Figure : System 1 configuration

System 2 shown in Figure 5 is the system modified with UDFTs and co-digestion with food waste in a fixed dome digester.

Figure : System 2 configuration

Comparing these two approaches simplifies the analysis, as both approaches satisfy the framework condition that nutrients and water are both fully reused. Therefore, effects of nutrient pollution, synthetic fertilizer, landfill emissions, water resource depletion and drinking water treatment are similar in both systems, which is why they are neglected in this analysis and environmental effects can be reduced to greenhouse gas emissions. This approach does have some limitations discussed in chapter 6 but serves as a useful approximation to reach conclusions regarding the research questions.

The differences in the approaches, namely the difference in primary treatment and the resulting effects on secondary treatment as well as composting and urine storage, were investigated as described in the following sections. The effects of these differences were then quantified over time by estimating the different material quantities needed for the upfront investment as well as the benefits and downfalls arising from the systems. How the different treatment elements are dimensioned is described in their respective sections, but some general assumptions needed for dimensioning and estimation of economic and GHG-related investment costs that are relevant to multiple components are laid out in Tables 1 and 2. Where available, site-specific data was obtained locally via the consultation of construction companies, however, due to the lack of available data, sometimes general reference values with potentially high uncertainty margins had to be used.

| Parameter | Unit | Set value | Comment | References |

|---|---|---|---|---|

| Person-equivalents (PE) | - | 120 | - | - |

| Operational hours | h | 10 | Estimates peak flow | - |

| Temperature (T) | °C | 25 | Nighttime average | World weather online (2022) |

| Exchange rate | USD GHS-1 | 0.13 | Last 5 years falling trend from 0.23 to 0.13 | Xe.com Inc. (2021) |

| LPG price | USD kg-1 | 1 | Fluctuates between 0.25 and 1.3 $ kg-1 in Ghana | Asante et al. (2018) |

| Parameter | Unit | Set value | Comment | References |

|---|---|---|---|---|

| Brick dimensions | cm-cm-cm | 20-10-10 | Local reference value | - |

| Brick density | kg m-3 | 1890 | Medium brick density | Amin Al-Fakih et al. (2018) |

| Brick cost | USD | 0.09 | Local reference value | - |

| Brick carbon footprint | kgCO2-eq kg-1 | 0.195 | Can vary significantly, for clay fired bricks value can be as high as 2.7 and for sun-dried bricks as low as 0.12 | Dabaieh et al. (2020); Kulkarni and Rao (2016) |

| Mortar between bricks | cm | 1 | Local reference value | - |

| Mortar cost | USD m-3 | 190 | Local reference value | - |

| Mortar carbon footprint | kgCO2-eq m-3 | 300 | 207-574 | Onn et al. (2019) |

| Concrete price | USD m-3 | 260 | Local reference value | - |

| Concrete carbon footprint | kg CO2-eq m-3 | 420 | Value for South Korea, no estimates available for Ghana | Paik and Na (2019) |

| Rebar in concrete | kg m-3 | 70 | Local reference value | - |

| Rebar cost | USD kg-1 | 0.43 | Local reference value | - |

| Rebar carbon footprint | kgCO2-eq kg-1 | 3.84 | Value for South Korea, no estimates available for Ghana | Baek et al. (2016) |

| Cast iron cover plate thickness | cm | 2.5 | - | - |

| Cast iron density | kg m-3 | 7100 | Found to vary between 6969 and 7242 kg m-3 | Fatahalla et al.(1996) |

| Cast iron plate cost | USD | 19.5 | 0.36 m2 plate, local reference value | - |

| Cast iron carbon footprint | kgCO2-eq kg-1 | 2.0 | 1.0-3.9 | Lisienko et al. (2016) |

| Additional piping length System 2 | m | 150 | Pipes for Blackwater and Urine respectively | - |

| Additional piping cost System 2 | USD | 700 | Pipes for Blackwater and Urine; Local estimate | - |

| Additional piping carbon footprint System 2 | kg CO2-eq m-1 | 27.1 | Pipes for Blackwater and Urine | Baldasano Recio et al. (2005) |

| Construction cost relative to material cost | - | 1.3 | Calibrated with local data on 20m3 digester and within upper boundary of factor 2 determined by the reference | J Behrendt et al. (2006) |

Piping effects were fixed to the project estimate, which is why they won’t change when input parameters are sensitized. Differences in operation and maintenance (O&M) costs strongly depend on the skill level of operators, the availability of specialized companies, the type of UDFTs used, wage levels and management style. It was not attempted to quantify O&M differences within the scope of this thesis, as this would have required calibration data and a more in-depth socioeconomic analysis. It was assumed that O&M differences are small compared to the factors investigated but further work is needed to properly embed this factor into decision-making.

Toilet characteristics

UDFTs in system 2 are compared against a standard dual-flush toilet (SDFT) in system 1. Along with price differences, Table 3 shows toilet flushwater use for urine and feces. Urination and stool frequencies are assumed to be independent. In the case of system 2, it is assumed that no crossflow of water occurs, meaning flushwater from urinations fully ends up with the urine and flushwater from defecations only goes to the FDD. Standard figures for flushwater consumption and UDFT cost correspond to the only model available in Ghana, which is the Laufen Save! toilet. This toilet does have some crossflow in order to be able to flush toilet paper, however it can be largely reduced by pushing the button only shortly, which is why this crossflow was not considered.

| Parameter | Unit | Set value | Comment | References |

|---|---|---|---|---|

| Flushwater for flushing of feces (UDFT and Standard toilet) | L | 6 | Depending on UDFT model 2-6 | González-Salgado (2017 |

| Stool frequency | d-1 | 1.10 | Can range from 0.74 to 1.97, 1.1 is average value | Rose et al. (2015) |

| Urination frequency | d-1 | 6.0 | Suggested design value | Rose et al. (2015) |

| Flushwater diluting Urine (UDFT) | Liters per flush | 0.15 | Depending on UDFT model 0.2-3; Laufen Save! 0.15 | González-Salgado (2017) |

| Flushwater for flushing of urine (SDFT) | Liters per flush | 3 | Özel and Baykal (2013) | |

| Price of UDFT | USD | 950 | Between 346 and 780€; Laufen Save! 950$ (Ghana) | González-Salgado (2017) |

| Price of standard dual flush toilet (SDFT) | USD | 300 | Local suppliers charge between 2000 and 4000 GHS (260-520 USD) | - |

| PE per toilet | - | 25 | Should not be higher than 25 | Gutterer et al. (2009) |

| Cost of biogas utilization | USD | 2200 | Gas storage in bags (15m3), desulfurization, dehydration, measurement equipment, based on project data | - |

Substrate characterization

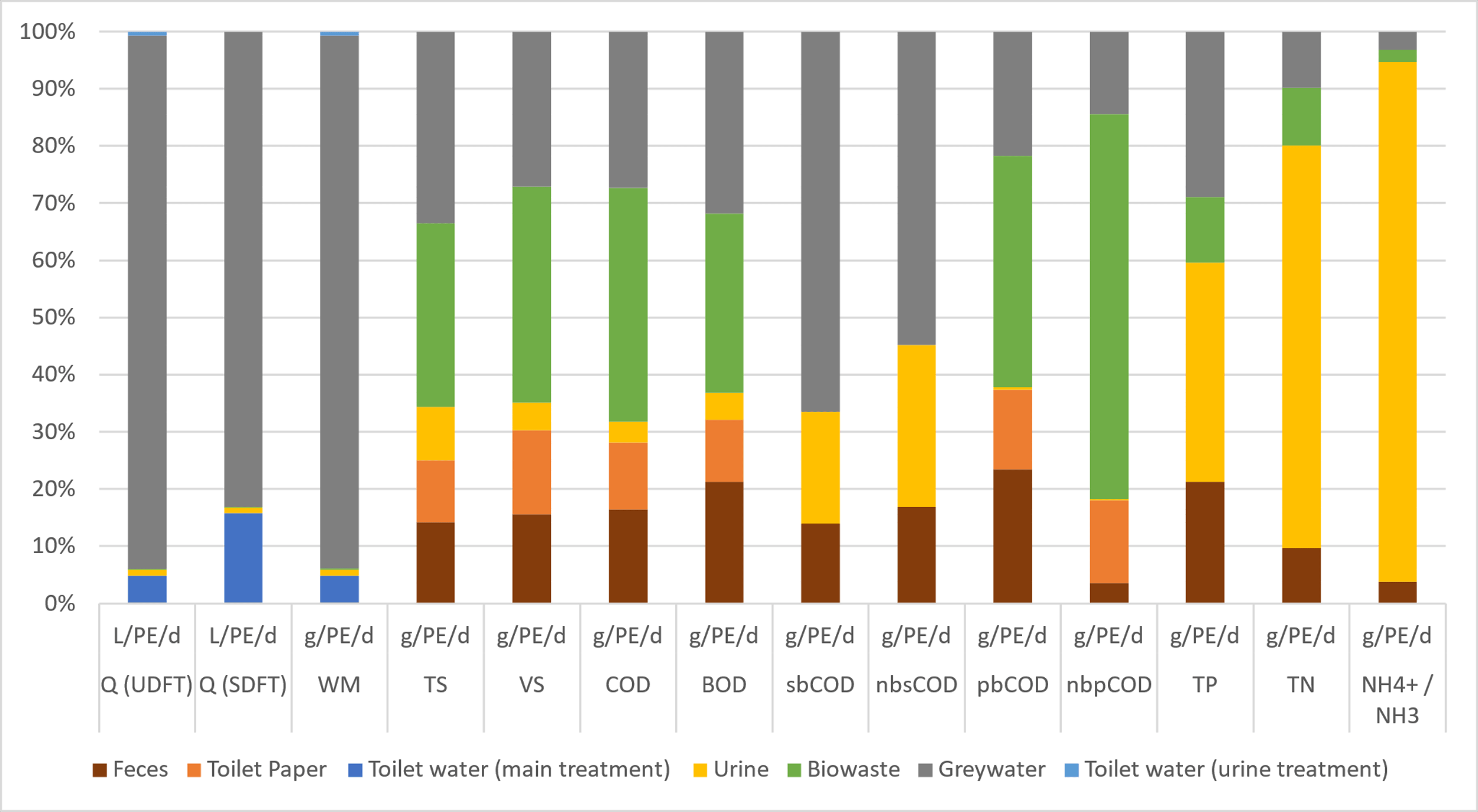

Wastewater composition is modelled according to data used by the URWARE model (H Jönsson et al. 2005). The model did not contain volumetric estimates for feces, biowaste and toilet paper. Therefore the density of feces was added with 1.06 mg L-1 (Brown et al. 1996), food waste density was measured with samples from the case study to be 1.13 mg L-1 when submerged underwater and toilet paper volume was neglected. However, both of the resulting volumes are small with respect to the other sources, as seen in Figure 6. Any solutes and particulates in toilet water were neglected as well. Figure 6 shows how different wastewater sources contribute to the relevant wastewater parameters.

Figure : Adjusted substrate characterization based on URWARE data (H Jönsson et al. 2005). Q-Discharge, UDFT - Urine diverting flush toilet, SDFT – Standard dual flush toilet, WM – Wet mass, TS – Total Solids, VS – Volatile Solids, COD – Chemical Oxygen Demand, BOD, Biochemical oxygen demand, sbCOD – soluble biodegradable COD, nbsCOD – non biodegradable soluble COD, pbCOD – particulate biodegradable COD, nbpCOD – non biodegradable particulate COD, TP – Total Phosphorus, TN – Total Nitrogen

The URWARE model based its input figures on data from Swedish households, however they generally align with similar data collected by (Rose et al. 2015) and (Larsen et al. 2013, p. xii). Data for the Global South has not been collected broadly regarding some of the parameters such as the fractionation of chemical oxygen demand (COD) used later on. (Rose et al. 2015) identified that the wet mass of fecal matter differs significantly between high- and low-income countries, however as this difference is small compared to the flushwater used, the model was not adjusted. The input fractionation demonstrates that feces, toilet paper, biowaste and toilet flushwater for feces constitute 69% of COD while only occupying 15.8% of volume in the case of SDFTs and 5.0% when UDFTs are used. Compared to a SDFT, the UDFTs can save 70% of water by reducing flushwater consumption for urine.

Digestion and Emission Modelling

Many models for anaerobic digestion have been put forward with varying degrees of complexity. Simpler models often directly estimate the quantity of biogas produced for specific substrates based on volatile solids, rendering them useless for analysis of the digestion process. Complex models like the Anaerobic Digestion Model 1 (ADM1) require many input parameters, of which data are often not or hardly obtainable. (Kythreotou et al. 2014, p. 712)

As complexity is not of much use when input data are generalized, such as in this analysis, and simpler models lack information to perform this analysis due to inabilities of determining effluent quality and gas composition, the medium complexity model URWARE (Jeppsson et al. 2005) was chosen as the main digestion model. However, this model had to be enhanced further to also model gas emissions from FDDs as it lacks the complexity to estimate emissions from compensation tanks as a function of substrate composition, dilution and PE served. Furthermore, the model needed to be merged with the DEWATS design guidelines on dimensioning the different treatment components. As the URWARE model is only valid for fully mixed digesters, the DEWATS model needs to provide necessary information for adjustment regarding the other reactors used.

The URWARE model estimates gas production based on how the different COD fractions are degraded. Using its standard parameters in its mode 1, 95% of the biodegradable soluble COD (bsCOD) and 60% of the particulate biodegradable COD (bpCOD) is converted to methane. Via the combustion equation CH4 + 2O2 → CO2 + 2H2O, it can be determined that CH4 has a COD of nearly 4 kg. CO2 cannot use oxygen as an electron acceptor and therefore does not contain any COD. COD of other trace gases is neglected. This way, CH4 production could be estimated via the input COD fractionation. Using other standard assumptions that set the protein content to 30%, the lipid content to 35% and the fraction of carbohydrates to 35%, CO2 production can be estimated based on CH4 production. The assumptions result in a ratio of 1.47 moles of CH4 per mol of CO2. (Jeppsson et al. 2005)

Emissions and gas collected were then converted using data from Table 4 to estimate climate impact by replacement of LPG. This assumed that gas conversion efficiencies of stoves are independent of the type of gas used.

| Parameter | Unit | Set value | References |

|---|---|---|---|

| CH4 net calorific value | MJ kg-1 | 55.6 | Dincer et al. (2018) |

| LPG net calorific value | MJ kg-1 | 47.3 | Dincer et al. (2018) |

| LPG emission factor | kg CO2-eq GJ-1 | 63.1 | Juhrich |

| CH4 Global Warming potential (100 yr) | kgCO2-eq kgCH4-1 | 28 | Stocker (2014) |

Fixed-Dome Digester

Feces, toilet paper, the toilet water from UDFTs used for feces, and biowaste enter the FDD in system 1. The different input parameters outlined in the previous section were compiled accordingly. Fixed parameters used for calculations regarding the fixed-dome digester are shown in Table 5.

| Parameter | Notation | Unit | Set value | Comment | References |

|---|---|---|---|---|---|

| HRT | tHRT | d | 30 | Generally ranges between 15 to 40 days in the Global South depending on Temperature and degree of mixing | Gutterer et al. (2009) |

| Gas retrieval rate | rretrieval | d-1 | 1 | - | - |

| Maximum relative gas pressure | prel | Pa | 15,000 | gives height of compensation chamber above lower end of dome | Vögeli et al. (2014) |

| Maximum absolute gas pressure | pmax | Pa | 116,300 | assuming ambient pressure 101,300 PA | - |

| Average absolute gas pressure | p | Pa | 108,800 | - | |

| Gas losses due to leaks, incomplete oxidation and gas releases | Lother | - | 0.05 | Between 0 and 10% for leaks, overall up to 40% | (Bruun et al. 2014) |

| Length & witdh of connection to compensation tank | lC | m | 1 | Local reference value | - |

| Height of connection to compensation tank | hC | m | 0.5 | Local reference value | - |

| Henry constant CH4 | KH,CH4 | mol (m3)-1 Pa-1 | 1.37494E-05 | Temperature adjusted | Sander (2015) |

| Henry constant CH4 | KH, CO2 | mol (m3)-1 Pa-1 | 3.31287E-04 | ||

| ideal gas constant | R | m3 Pa K-1 mol-1 | 8.3145 | ||

| Peak flow factor | PQ | - | 2.4 | based on assumption of uniform distribution during operating hours |

The following system of nonlinear equations was set up to determine the fractions of CH4 and CO2 that leave the system dissolved, are collected in the dome, and leave the system through the compensation tank respectively. The system was solved iteratively. The geometry of the FDD had to be generalized for any input parameters to allow for sensitivity analysis. Volume in the digester for accumulated sludge was not considered as it is assumed to be fully mixed. The bottom of the digester is meant to be flat. Table 6 shows and explains the parameters calculated.

| Parameter | Notation | Unit | Parameter | Notation | Unit |

|---|---|---|---|---|---|

| Volume of cylinder (main digestion part) | VL = \(t_{HRT}Q\) | m3 | Gas fractionation | fCH4 / CO2 | - |

| Volume of dome and compensation tank | VD = VCT | m3 | Gas produced | GP,CH4/CO2 | mol d-1 |

| Cylinder height | hCylinder | m | Gas in dome | GDome,CH4/CO2 | mol d-1 |

| Cylinder radius | rCylinder | m | Gas dissolved | Gdiss, CH4/CO2 | mol d-1 |

| Dome height | hDome | m | Gas in compensation tank | GCT, CH4/CO2 | mol d-1 |

| Time until compensation tank filled up again after withdrawal | tCT | d | Average fraction of compensation tank occupied | fCT | - |

\(\frac{f_{CH4}}{f_{CO2}} = \frac{G_{Dome,\ CH4}}{G_{Dome,CO2}}\), The equation provides that methane content in the dome equals the fraction of CH4 after losses were accounted for.

\(G_{Dome,\ CH4/CO2} = \ G_{P,CH4\text{/CO2}} - G_{diss,\ CH4\text{/}CO2} - \ G_{CT,\ CH4\text{/CO2}}\) This represents the mass balance of gas produced, dissolved and escaped through the compensation tank.

\(t_{CT} = \ \frac{V_{CT}}{QP_{Q} + V_{CT}r}\); \(f_{CT} = 1 - 0.5t_{CT}r\) Assuming withdrawals happen in the morning, these equations estimate how fast the compensation tank fills up due to new wastewater entering the digester and gas produced and therefore what fraction is on average occupied with digesting liquid.

\(V_{D} = \frac{\left( G_{Dome,CH4} + G_{Dome,CO2} \right)\frac{RT}{p}}{r}\) This calculates the volume of the dome and compensation tank based on withdrawal rate and how much gas is accumulating in the dome according to the ideal gas law.

\(G_{CT,CH4/CO2} = \ G_{P,CH4/CO2}\frac{f_{CT}V_{CT} + h_{c}l_{c}^{2}}{f_{CT}V_{CT} + h_{c}l_{c}^{2} + V_{L}}\ \)Based on the assumption that the digester is fully mixed, the equation estimates gas losses through the compensation tank depending on how much liquid is on average in it as well as the connector to it.

\(G_{diss,CH4/CO2} = K_{H,CH4/CO2}Qpf_{CH4/CO2}\) This formula estimates how much gas is dissolved based on Henry’s law.

\({(h_{Cylinder} + h_{Dome})}^{2} = r_{Dome}^{2} + h_{Cylinder}^{2}\) With this equation the geometry of the digester is determined based on the requirement that the dome can easily be constructed with a rotatable stick placed in the bottom-center of the digester.

\(V_{L} = \pi r^{2}h_{Cylinder}\) This formula relates the geometry requirement to the design HRT.

\(V_{Dome} = \ \pi\left( h_{Cylinder} + h_{Dome} \right)h_{Dome}^{2} - \frac{1}{3}\pi h_{Dome}^{3}\) This geometric equation interlinks dome height with dome volume

Effluent parameters were determined according to the URWARE model with 100% of original non-biodegradable soluble COD (nbsCOD) in addition to 5% of bsCOD converted to nbsCOD. Additionally, 100% of non-biodegradable particulate COD (nbpCOD) plus 15% of bpCOD, converted to nbpCOD, is discharged. Finally, 20% of bpCOD exits the system as biomass. The effluent biochemical oxygen demand (BOD) is modelled to be 65% of the effluent bsCOD and bpCOD. (Jeppsson et al. 2005)

For the material quantity estimation, according to local standards, all horizontal parts are made of reinforced concrete with a thickness of 15 cm while vertical walls and the dome are made of brick. Bricks of walls are arranged to have wall thicknesses of 20 cm, while for the dome construction bricks are arranged longitudinally resulting in a thickness of 10 cm. However, to seal the system gastight, an additional 10cm thick layer of mortar is applied to the dome.

Imhoff tank

The Imhoff tank was designed according to standard DEWATS guidelines (Gutterer et al. 2009). Table 8 shows the external input values used, which are default values in the DEWATS guidelines.

| Parameter | Unit | Set value |

|---|---|---|

| HRT | H | 1.5 |

| Desludging interval | Yr | 1 |

| Inner flow tank width | m | 1.30 |

| Space beside flow tank | m | 0.55 |

Feces, toilet paper, urine, greywater and flushwater from SDFTs were added to form the influent according to system 1. The fraction of COD contained by settleable solids needed for this approach was assumed to be equal to the fraction of particulate COD to total COD. The COD/BOD5 ratio was determined via the URWARE input values to 1.86. The URWARE model however uses BOD7, but the value obtained is sufficiently close to the suggested standard value of 1.9 that the DEWATS guidelines use for municipal wastewater. Effluent COD was estimated via the empirical DEWATS formula relating HRT and settled COD. The bsCOD and nbsCOD were presumed to pass through the Imhoff tank unaffected and output values of bpCOD and nbpCOD were assumed to have equal settling properties. Both these assumptions are also used in the URWARE model for settling applications. Conversion from particulate to soluble COD during digestion of the settled solids was neglected. BOD5 effluent was determined via the empirical formula provided by DEWATS guidelines relating BOD removal to COD removal depending on the input COD/BOD fraction. The COD producing biogas was estimated to be 60% of settled bpCOD according to URWARE, which amounted to 2.1 kg COD converted to methane.

The geometry of the tank was designed according to the exemplary drawing provided in Chapter 9 of the DEWATS guidelines using the parameters set earlier and adjusting to the calculated sludge height, total inner length and width, sludge height and depth of the outlet based on design results. It can be found in the appendix.

Anaerobic baffled reactor

The anaerobic baffled reactor was designed according to standard DEWATS guidelines (Gutterer et al. 2009). Table 9 shows the external input values used, which are default values in the DEWATS guidelines.

| Parameter | Unit | Set value | Comment |

|---|---|---|---|

| Desludging interval | yr | 1 | Corresponding to FD |

| Peak factor | - | 2.4 | Corresponds to 10 h of operation |

| Desired effluent BOD | Mg L-1 | 30 | Value set as highest practically achievable based on DEWATS experience |

| HRT settler | h | 1.5 | Standard DEWATS value |

| Depth at outlet | m | 1.5 | |

| Settler depth | m | 1.5 | |

| Maximum upflow velocity | m h-1 | 1.8 | |

| Length of one downflow shaft | m | 0.25 |

Substrate input values were calculated according to the determined FDD and Imhoff tank effluents respectively. In scenario 2, greywater was added to the FD effluent. The fraction of COD contained by settleable solids needed for this approach was assumed to be equal to the fraction of particulate COD to total COD as in the calculations for the Imhoff tank.

Firstly, BOD and COD degradation was estimated in the integrated settler using DEWATS guidelines and the parameters listed in Table 9. It was assumed that bsCOD and nbsCOD pass through the settler unaffected and bpCOD and nbpCOD have equal settling properties as suggested by URWARE model assumptions. Moreover, COD used for gas production was calculated as 60% of settled bpCOD.

Secondly, the main part of the ABR was dimensioned with the obtained effluent of the internal settler. This was done with DEWATS guidelines and the values provided. The estimation of COD degraded had to be modified as the guidelines contained an error leading to possible removal rates over 100% and a non-continuous removal function based on the number of chambers added. The case differentiation “less than 7 chambers” was replaced with “less than 4 chambers” to fix this error. Calculations were performed for zero to ten upflow chambers to determine the lowest number of chambers necessary to achieve a certain BOD set as an input value. Both systems can therefore be compared regarding their efficiency since they can be assumed to be similarly effective. Additionally, calculated values were not rounded up as done in the guidelines. Upflow chamber length was set to half the water depth as the highest recommended value.

Degradation of bsCOD was set to equal BOD degradation, but if the BOD value was higher, then the difference was added as bpCOD. COD converted to CH4 in the baffles was assumed to be 95% of bsCOD and 60% of bpCOD as per the URWARE model.

The geometry of the tank was designed in accordance with the exemplary drawing provided in Chapter 9 of the DEWATS guidelines found in the appendix. The drawing was adjusted with design results, namely the calculated inner settler length, the number of chambers, and chamber width. Settler width was chosen to be the upflow chamber width calculated to allow for a more compact design. Wall strength of the brickwork was reduced from 23 cm to 20 cm to meet Ghanaian brick standards and allow comparability towards the FDD. Gas space over the inlet was set to 0.25 m and thickness of the cover was assumed to be as strong as the foundation.

Urine treatment

To be properly reused, urine must undergo some form of treatment to eliminate pathogens. As it is assumed that all nutrients are reused this could be done in the post-treatment of the ABR effluent. However, then it would need to be designed larger, which is not accounted for in this analysis. Moreover, while the main wastewater is designed to irrigate crops for production, some food crops could also be irrigated safely with treated urine. Extended storage of urine has been identified as a simple and effective tool for pathogen control (Münch and Winker 2011). The authors suggested a storage time of 180 days for urine to be safely applied to food crops, although storage time can be reduced significantly if less strict pathogen control is required. Table 10 shows the assumptions from which the additional needed investment was calculated. Values regarding tank dimensions are based on data from local suppliers. Urine was assumed to be stored in polyethylene tanks locally known as polytanks. Space consumption was estimated with tanks assembled in an array with no space in between.

| Parameter | Unit | Set value |

|---|---|---|

| Storage time | d | 180 |

| Polyethylene carbon footprint | kg CO2-eq kg-1 | 3.64 |

| Polyethylene density | kg m-3 | 930 |

| Polytank cost | USD (m3)-1 | 117 |

| Polytank height | m | 1.5 |

| Polytank radius | m | 1.0 |

| Polytank thickness | m | 0.01 |

Greenhouse gas emissions from urine storage are poorly quantified in literature, but simulation data from Udert et al. (2003) revealed that even if all nitrogen lost was escaping as N2O, emissions would still be at least one order of magnitude below the total of other emissions calculated and therefore emissions from storage were not further considered. The carbon footprint of polyethylene has not been estimated for production in Ghana, however Dormer et al. (2013) found that life cycle emission rates were between 1.538 and 3.64 kgCO2-eq kgPolyethylene-1 depending on the fraction of polyethylene recycled. Crawford and Throne (2002) found that polyethylene densities are generally in the range of 925 to 940 kg m-3.

Composting

In Ghana, food waste is landfilled, used as animal feed, composted, utilized in anaerobic digestion or processed to bio-char briquettes (Galgani et al. 2014). As the comparison between systems is based on the effective reuse of all nutrients, composting of food waste in system 1 is one option that allows for an effective comparison to the food waste utilization in wastewater treatment in system 2. Composting causes significantly more emissions of N2O, which is why it negatively affects the greenhouse gas balance of system 1. Galgani et al. (2014) investigated processes for food waste composting in Northern Ghana and found that composting additionally causes 0.17 kgCO2-eq kg-1, comparing it with other studies putting the value between 0.06 and 0.99. As emissions from anaerobic digestion are already accounted for, absolute emissions from food waste treatment by composting estimated in the study to be 0.19 kgCO2-eq kg-1 were used. This could be done on the assumption that N2O emissions from anaerobic digestion are negligible. It was an assumption taken in the study, although it has been acknowledged that large uncertainties exist for both anaerobic digestion and composting. Fobil et al. (2005) found that the density average for different income levels vary between 410 and 540 kg m-3, with which emissions could be calculated for the food waste input substrate. Composting time largely depends on the operation and maintenance work invested and can range between twelve weeks and two years (Nardo 2011). Table 10 shows the parameters set for calculation of space and climate impact. Operation and maintenance costs were assumed to be similar between systems and were not included in the analysis. Capital investment and initial carbon footprint were assumed to be negligible.

| Parameter | Unit | Set value |

|---|---|---|

| Composting time | d | 90 |

| Food waste density | kg m-3 | 475 |

| Compost height | m | 1.5 |

| GHG emissions from composting | kg CO2-eq kg-1 | 0.19 |

Results

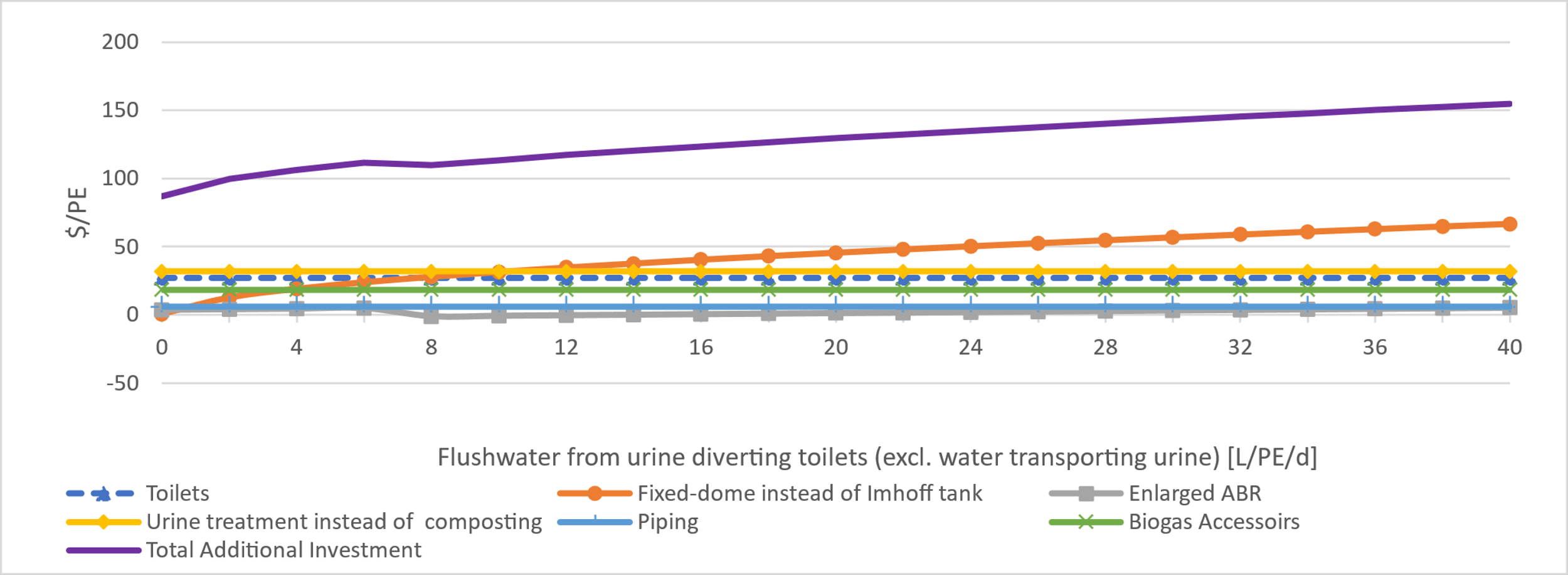

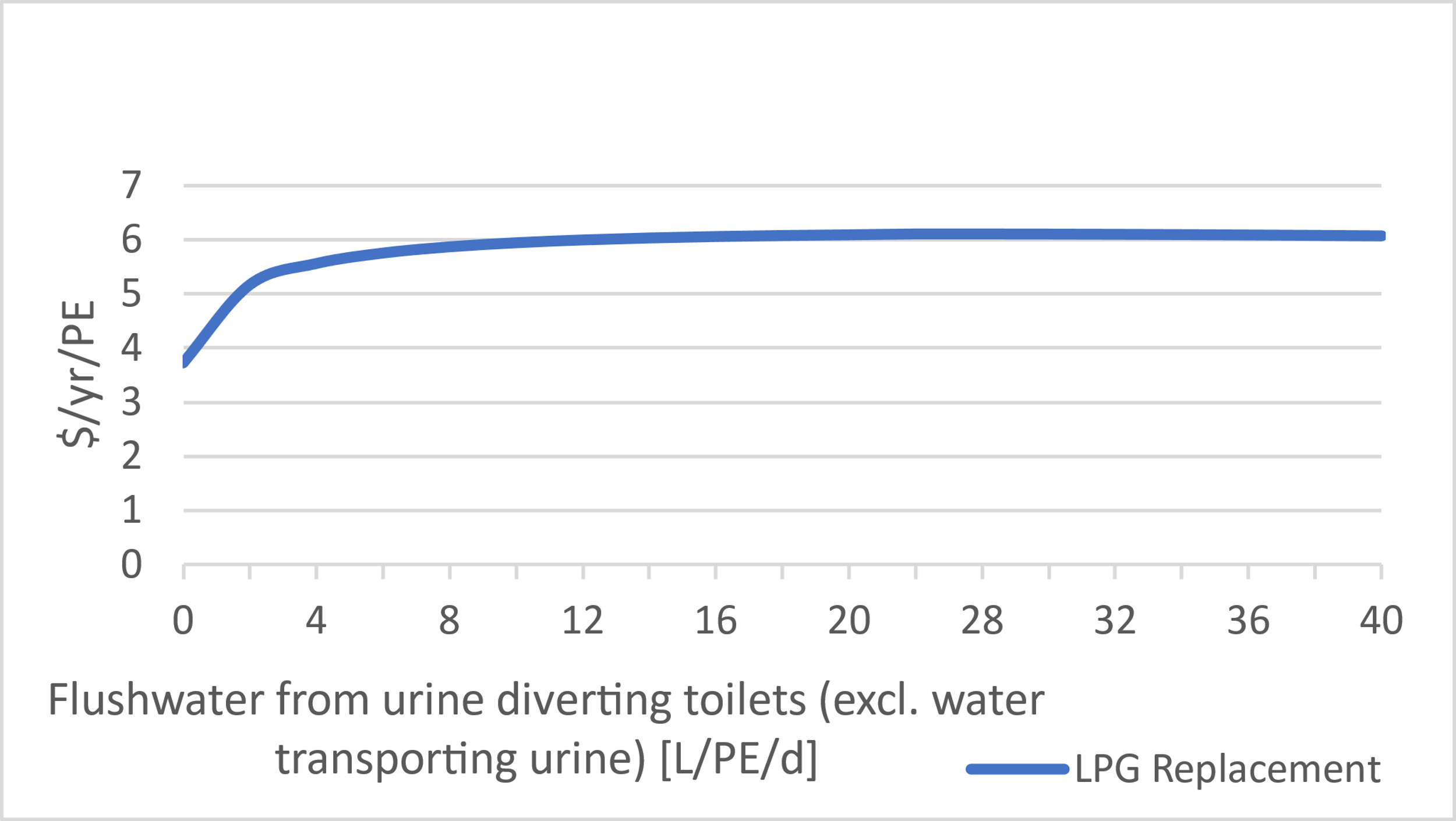

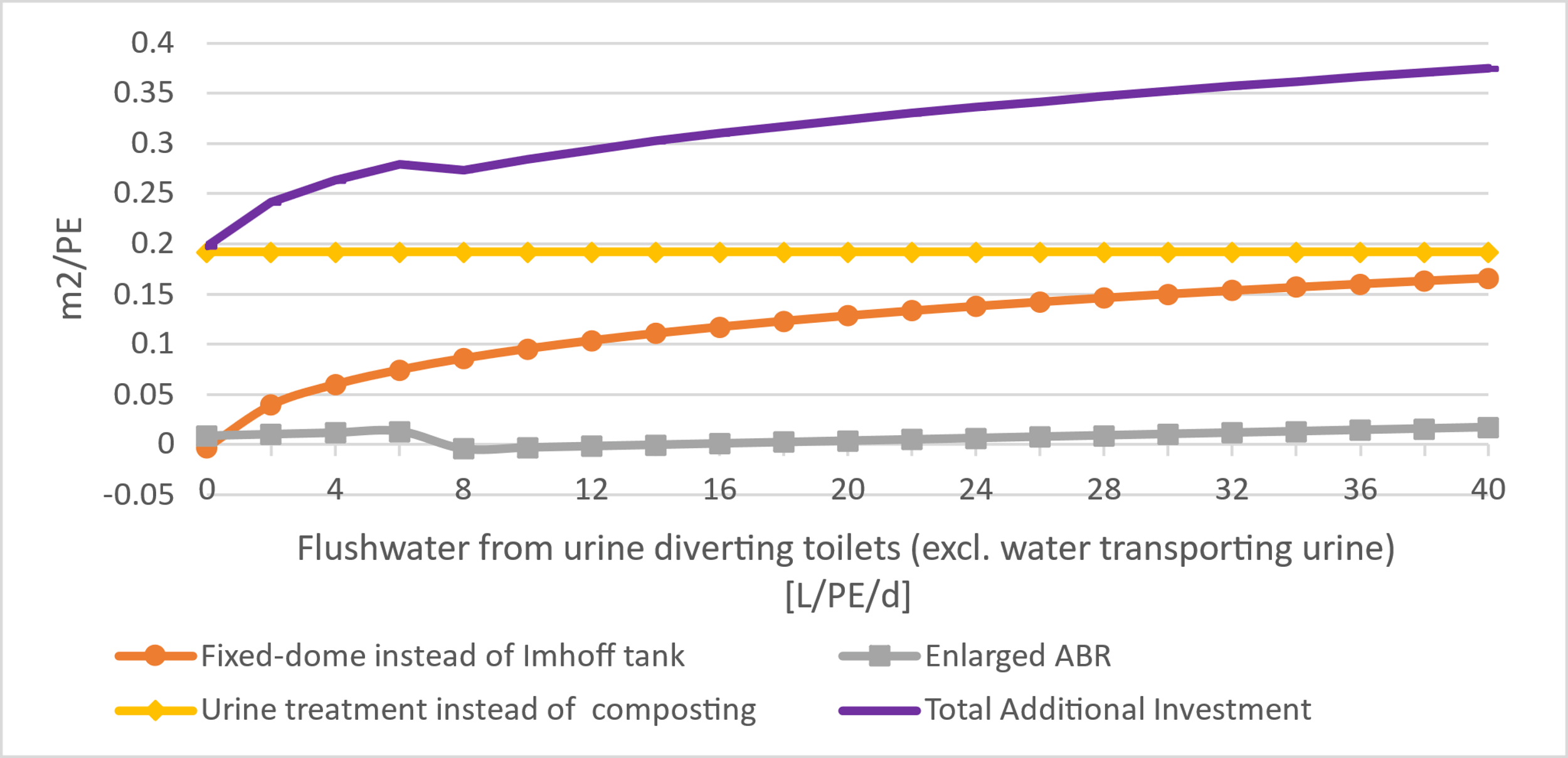

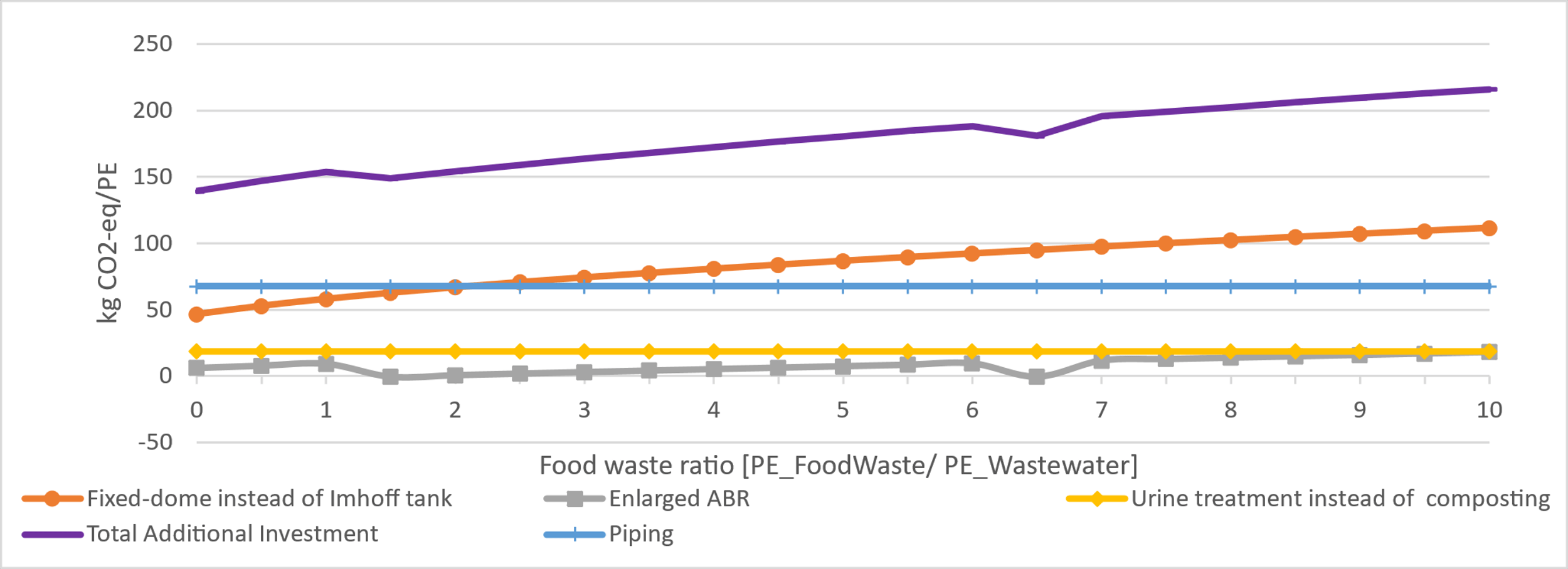

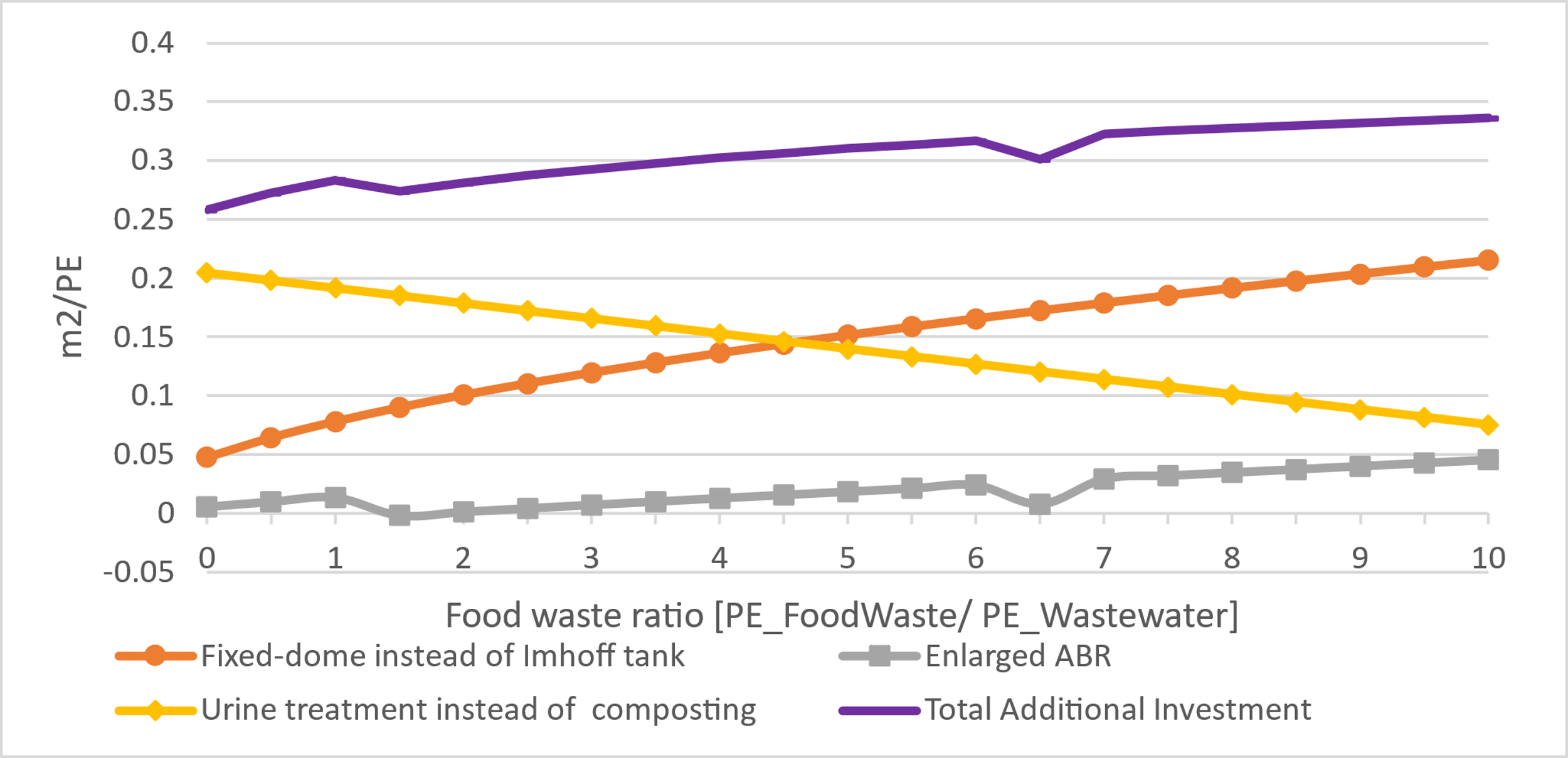

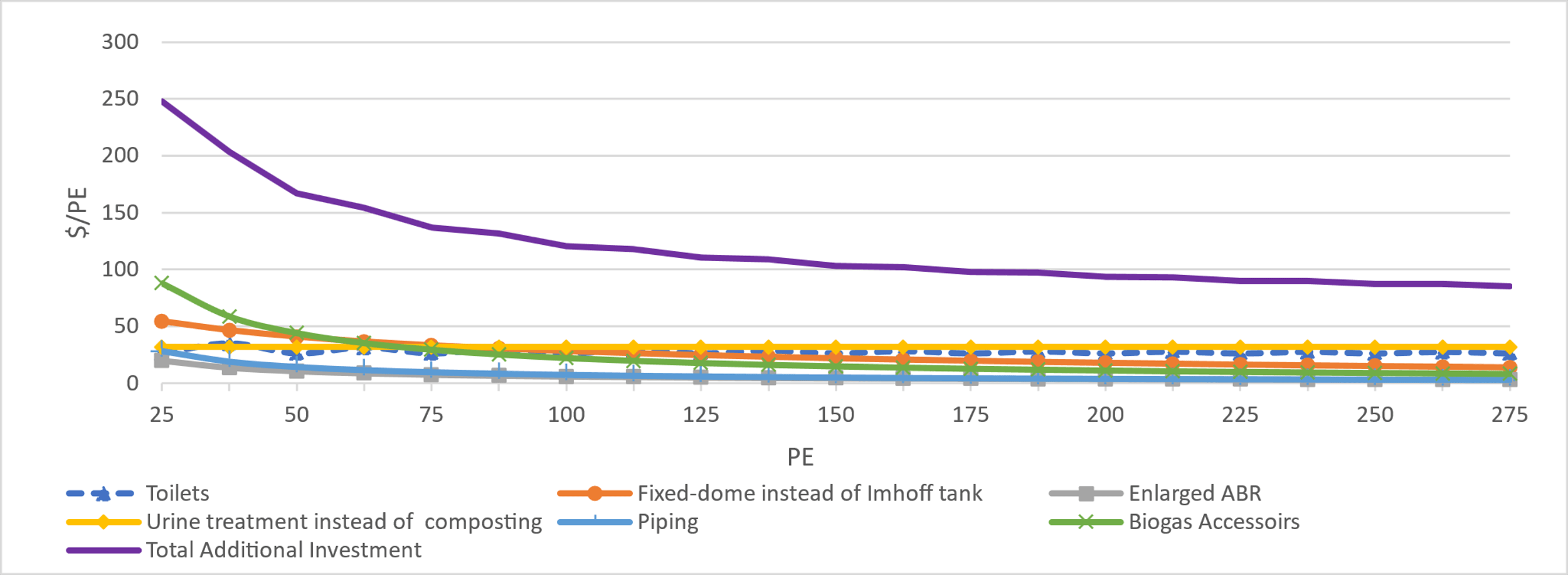

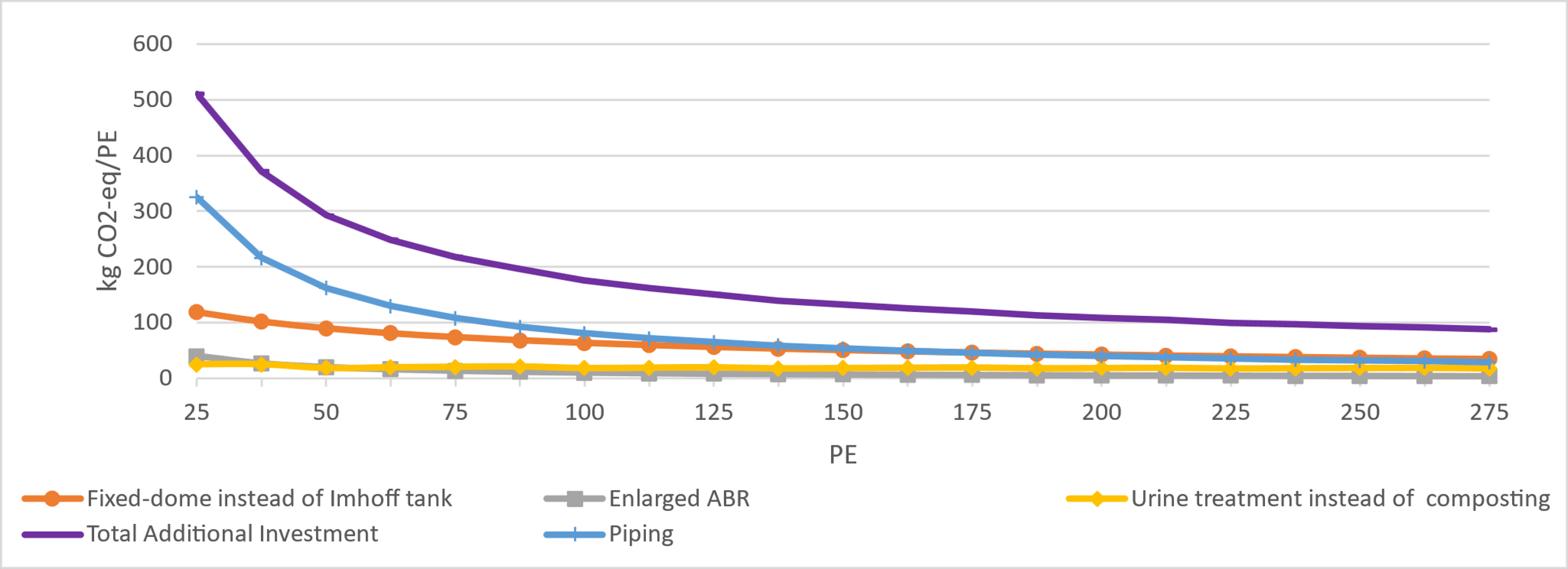

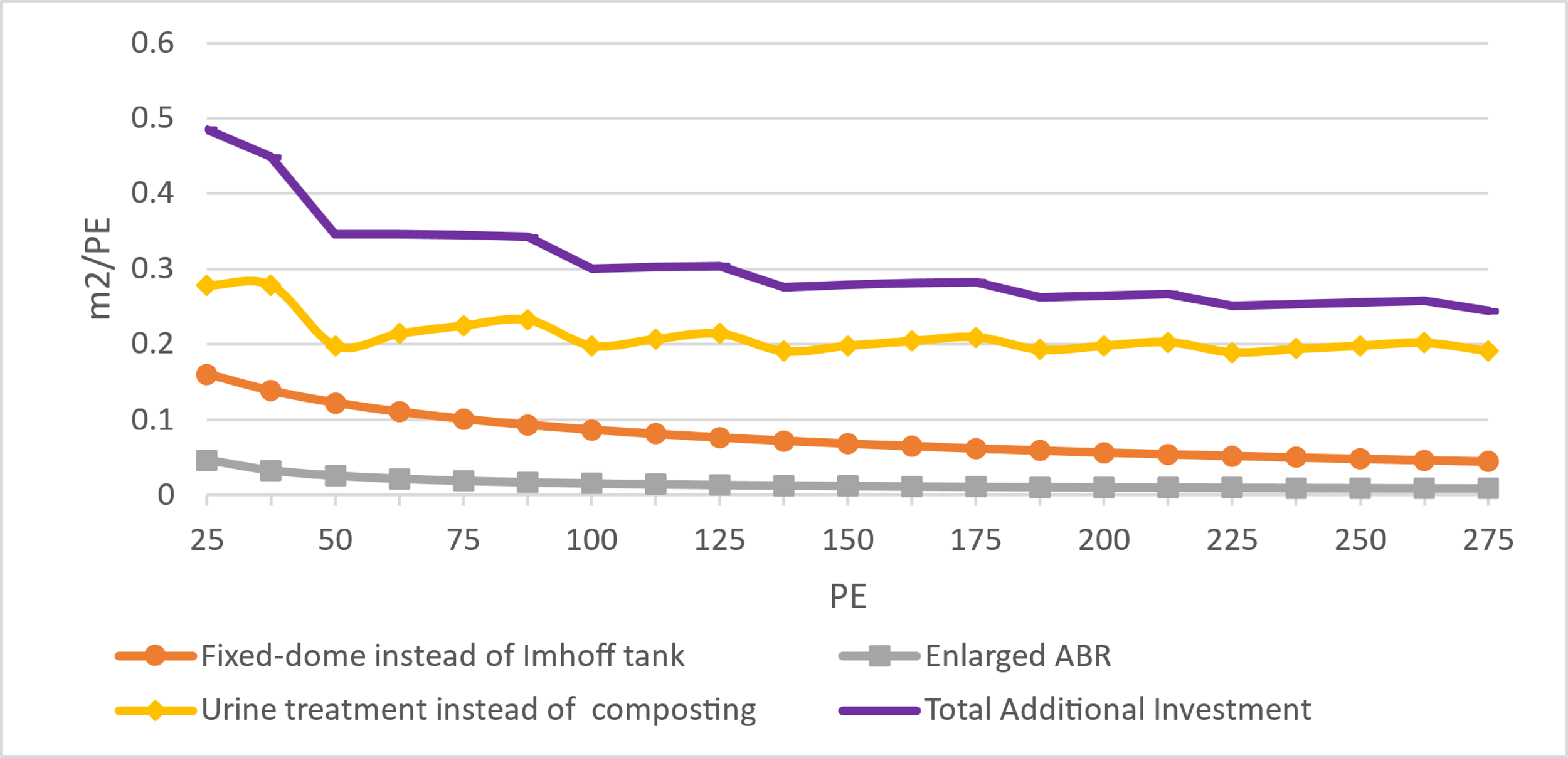

Compared over system 1, system 2 using UDFTs comes with a higher investment cost of 113 USD PE-1. The most significant factor was identified to be urine storage (32.1%) followed by the higher cost of UDFTs compared to SDFTs (23.9%) and substitution of the Imhoff tank with a FDD (22.2%). The costs due to biogas utilization equipment (16.2%), additional piping needed (5.2%), and ABR enlargement (4.5%) were comparably lower. Regarding greenhouse gas emissions, system 2 had and added carbon footprint of 154 kgCO2-eq PE-1, which was mainly attributed to additional piping needed (44.0%) and the FDD replacing the Imhof tank (37.8%). Emissions from construction of a larger ABR (16.7%) and urine treatment (12.1%) were less significant. The additional space consumption excluding gas storage was determined to be 0.28 m2 PE-1 due to urine storage (67.6%), the larger first treatment stage (27.6%), and larger ABR (4.8%).

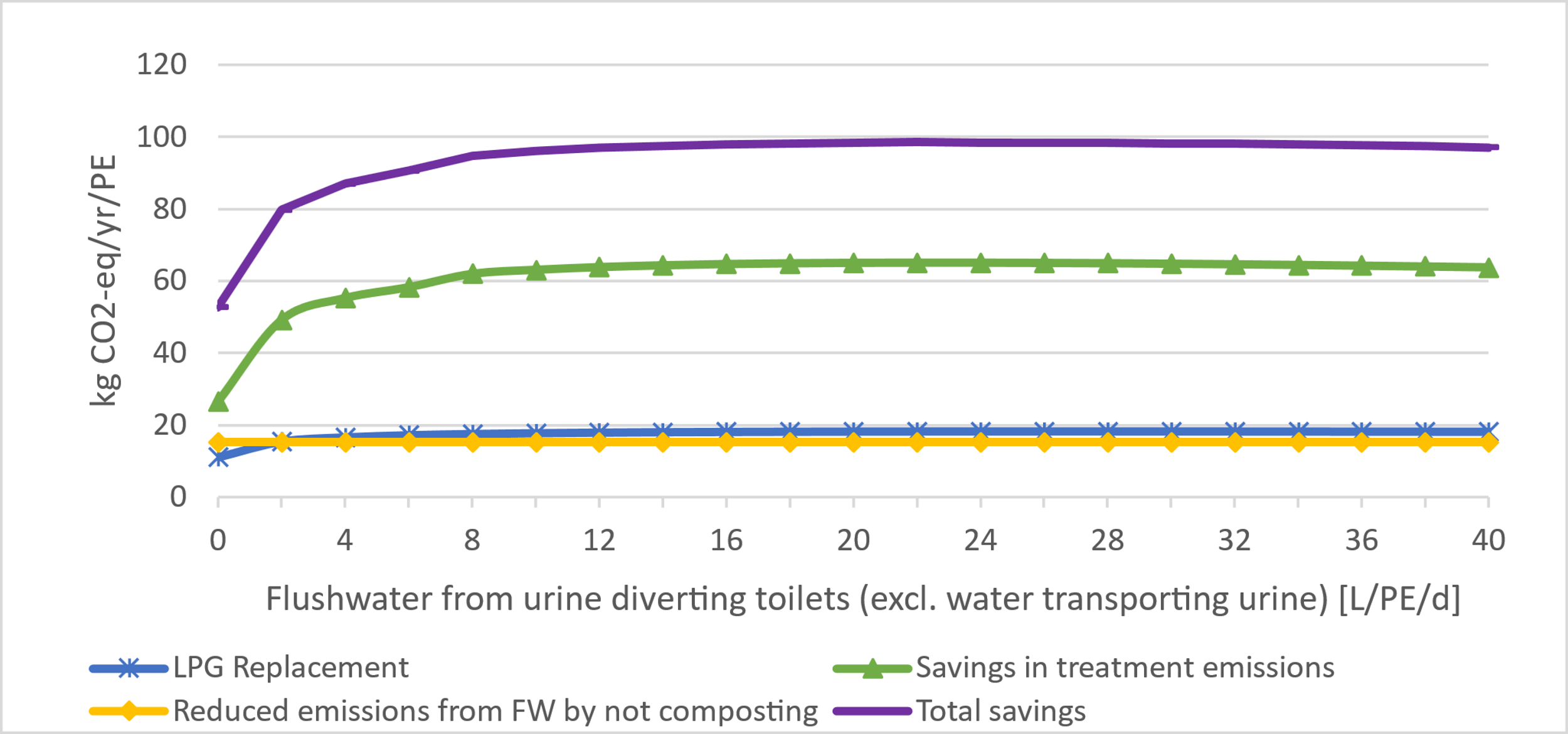

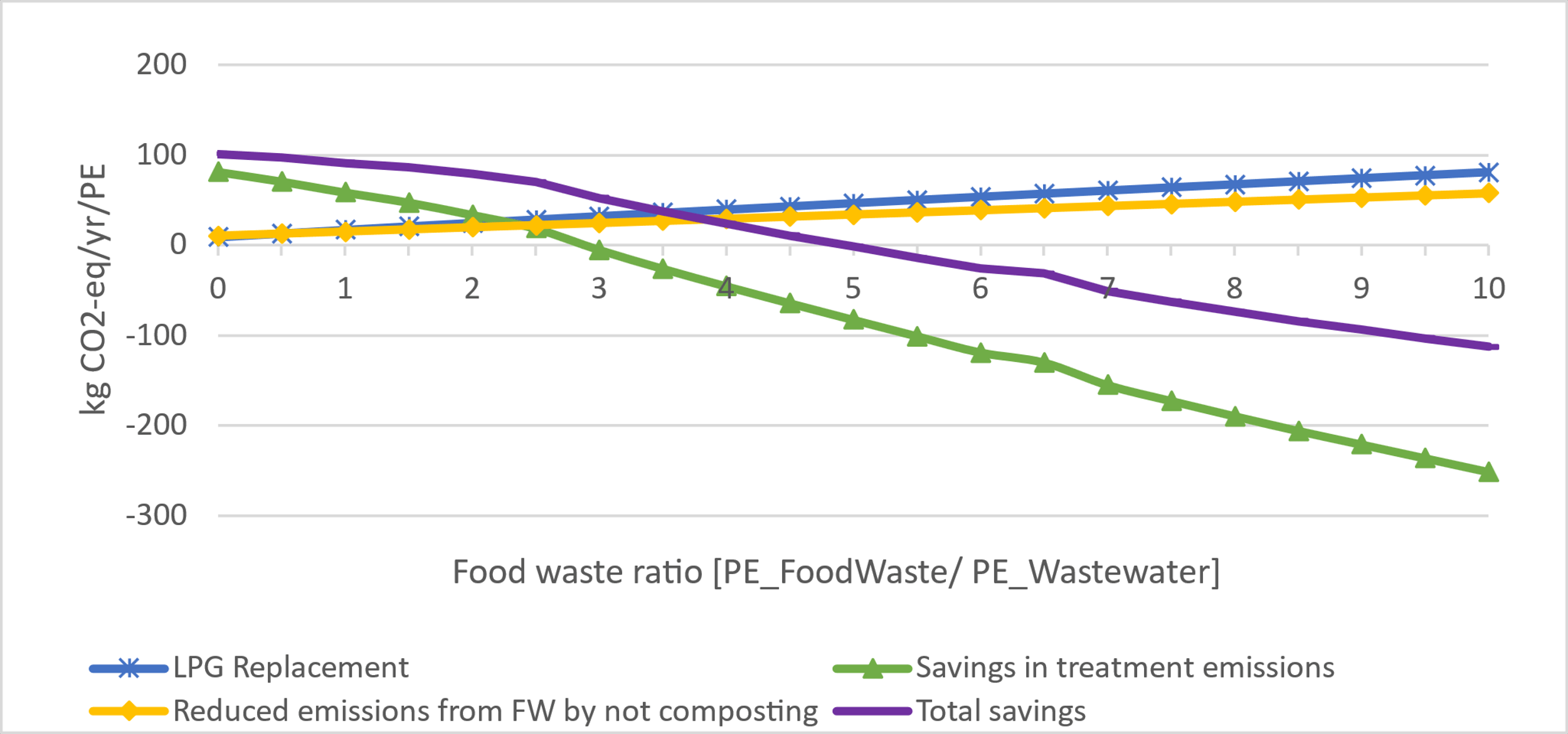

Use of biogas would constitute 5.8 USD PE yr-1 in savings. With regards to GHG emissions, 91.4 kgCO2-eq PE-1 yr-1 would be saved by the use of system 2. These savings consist of reduced emissions during treatment (64.4%), avoided emissions by LPG replacement with biogas (18.9%), and reduced emissions from food waste treatment (16.7%).

Accounting for the higher investment but also for the operational benefits provided by system 2, it was determined that financial investment would be returned after 19.5 years in contrast to initially higher GHG emissions being amortized in just 1.7 years. Over a lifespan of 20 years, 1.7 tCO2-eq PE‑1 are saved by the use of system 2 instead of system 1. With a hypothetical carbon price of 100 USD tCO2-1, this would combine to an amortization time of 8.6 years and 170 USD PE-1 saved, which scales up to 20400 USD for 120 PE.

These findings are illustrated in the Appendix. Part of the following sections give an overview on how these findings would change with respect to flushwater consumption, food waste dosage, gas losses, PE as well as LPG and carbon prices.

Gas production and emission

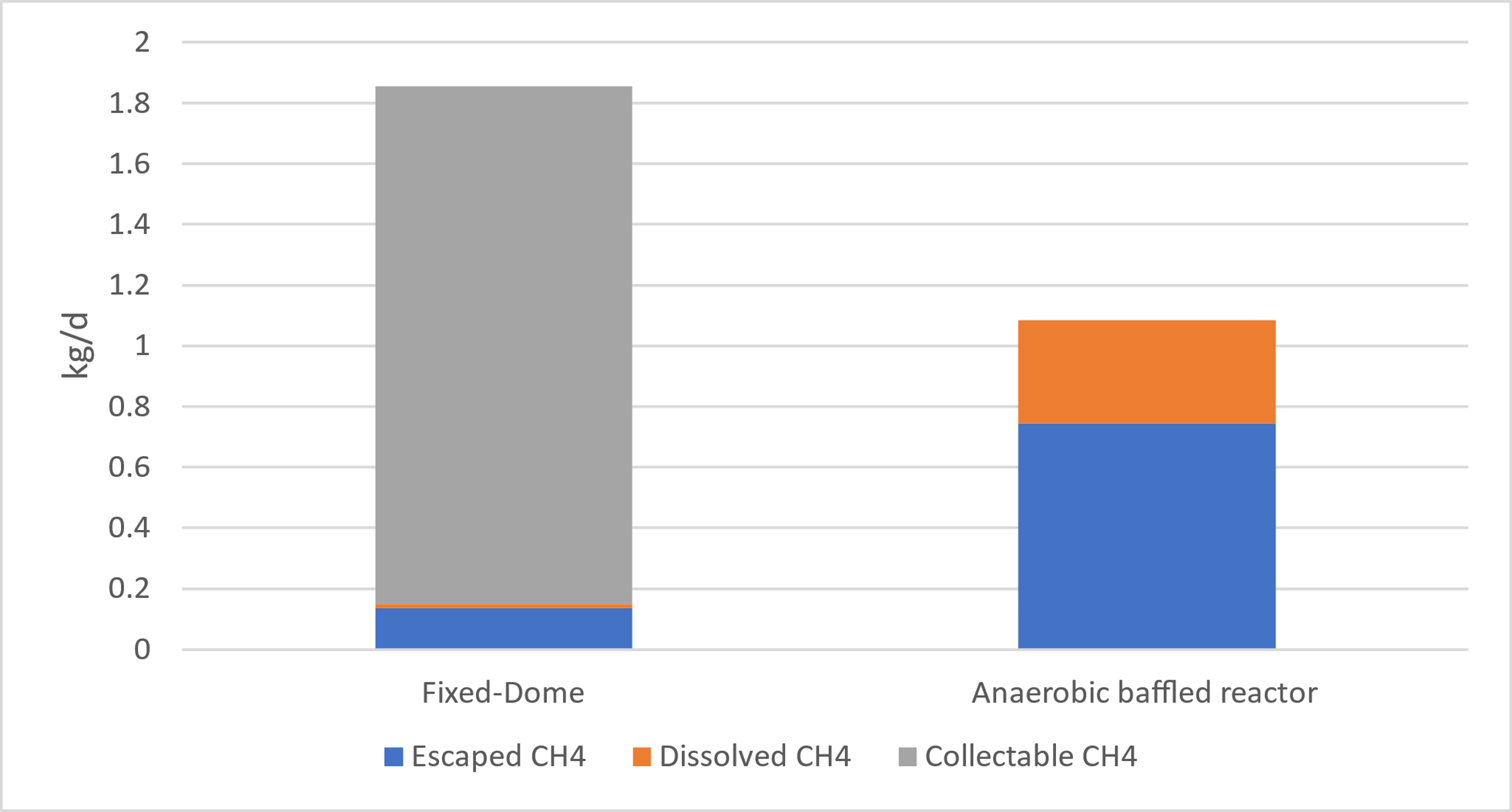

Figure 7 shows that 92% of gas

produced in the FDD can be captured. Most losses occur through the

compensation tank, with dissolved CH4 only playing a minor role. In the

ABR, 68% of gas produced could theoretically be captured if more

complicated capturing technology is available. 63% of gas produced was

modelled to be produced in the FDD but 88% of emissions would be caused

by the ABR.

Figure 7 shows that 92% of gas

produced in the FDD can be captured. Most losses occur through the

compensation tank, with dissolved CH4 only playing a minor role. In the

ABR, 68% of gas produced could theoretically be captured if more

complicated capturing technology is available. 63% of gas produced was

modelled to be produced in the FDD but 88% of emissions would be caused

by the ABR.

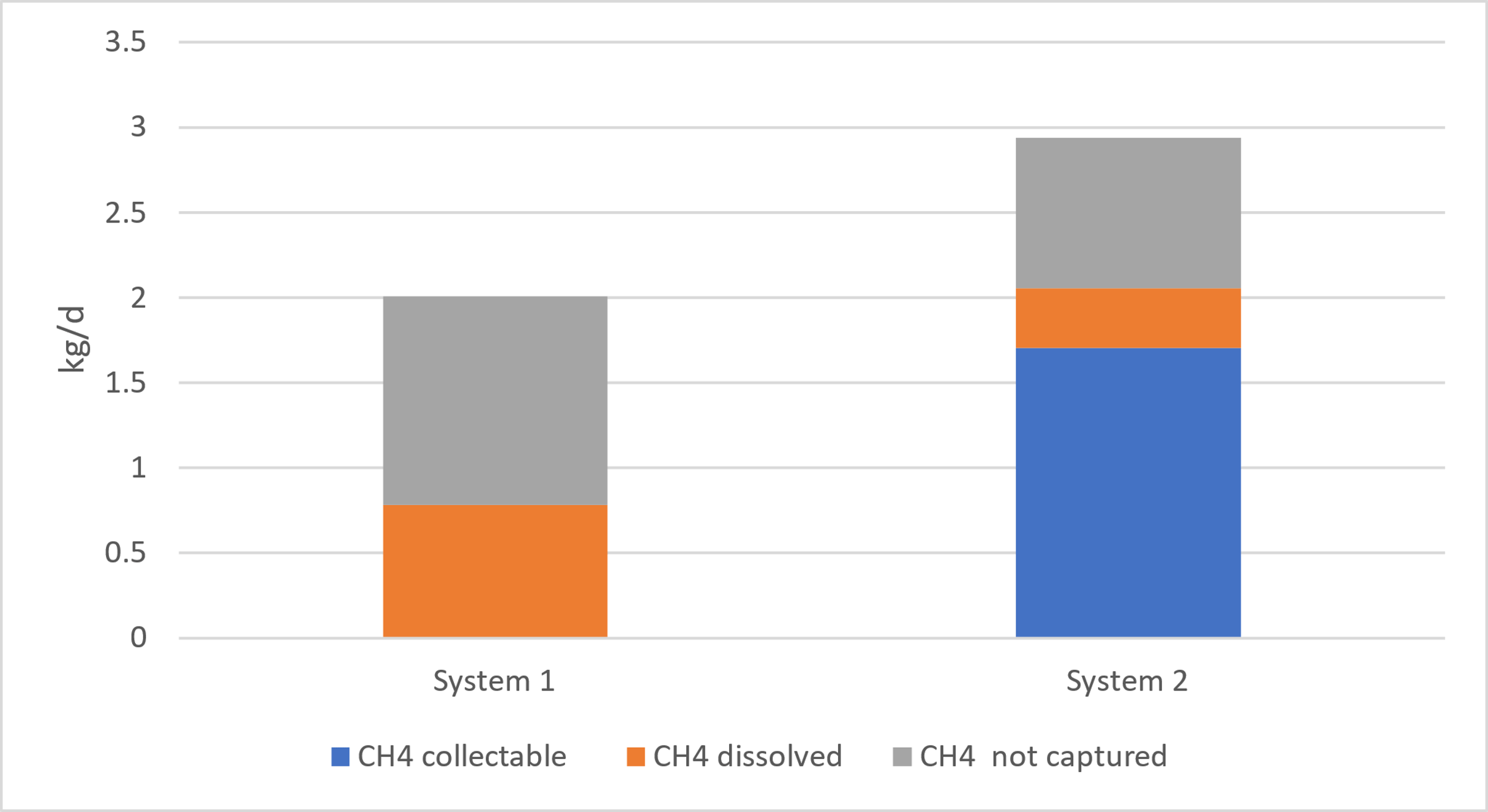

In Figure 8 it can be seen

that 34% of emissions can be mitigated by system 2. Gas production was

modelled to be 46% higher in system 2. However, only 55% of total gas

produced could be recovered. Even if all gas not dissolved could be

captured, system 1 would still have emissions 2.2 times higher.

In Figure 8 it can be seen

that 34% of emissions can be mitigated by system 2. Gas production was

modelled to be 46% higher in system 2. However, only 55% of total gas

produced could be recovered. Even if all gas not dissolved could be

captured, system 1 would still have emissions 2.2 times higher.

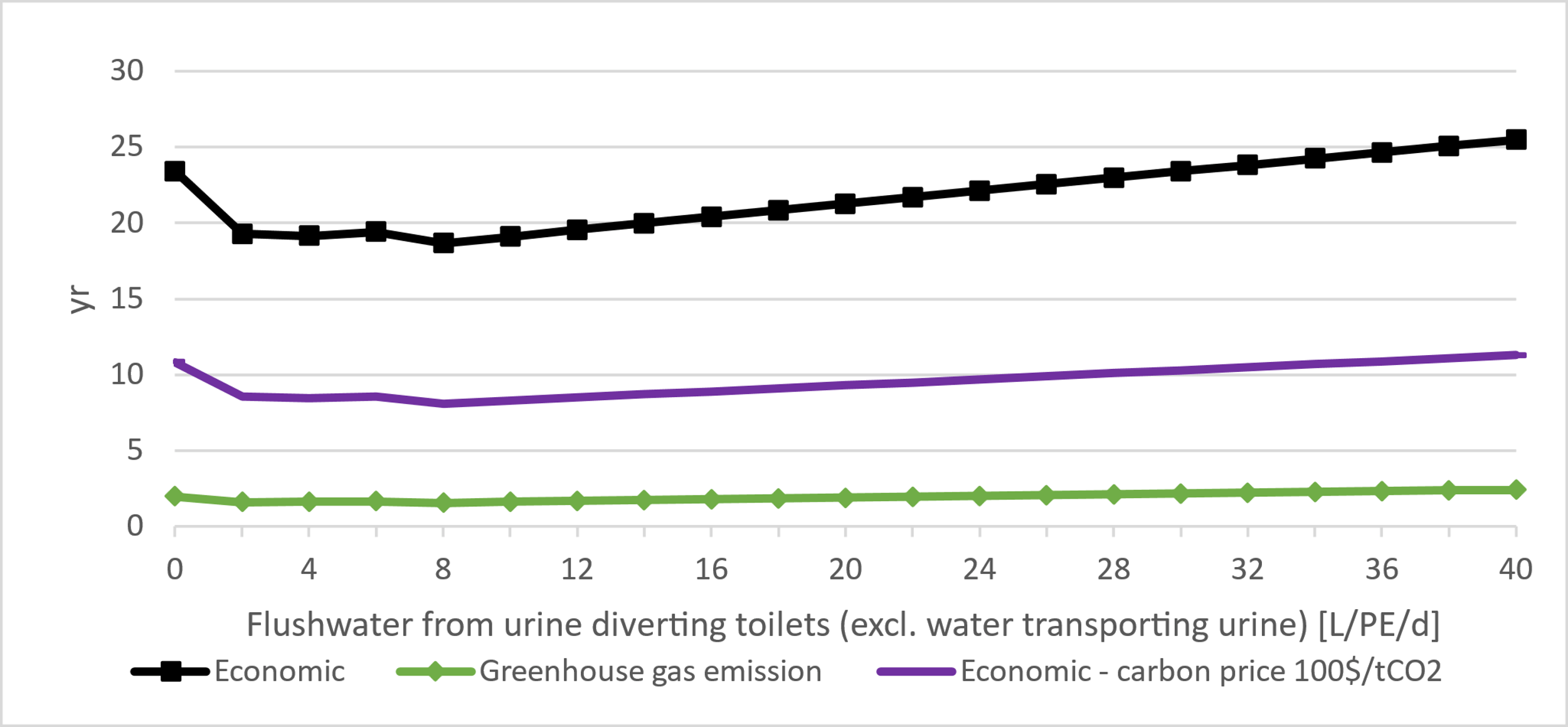

Flushwater consumption

Using the standard assumptions laid out in section 4.1, UDFTs have a flushwater consumption of 6.6 L PE-1 d-1 compared to SDFTs with 24.6 L PE-1 d-1. The differences in flushwater mainly had effects on the size of the FDD compared over the Imhoff tank, but smaller differences in ABR design were also observed. The settler of the ABR needs to be larger to compensate for the inorganic part of food waste added to the FDD. This effect is directly correlated to flushwater consumption. In low flush scenarios, one additional baffle is needed to achieve the same effluent quality. For flushwater of more than 8 L PE-1 d-1, the additional chamber is no longer needed due to dilution effects.

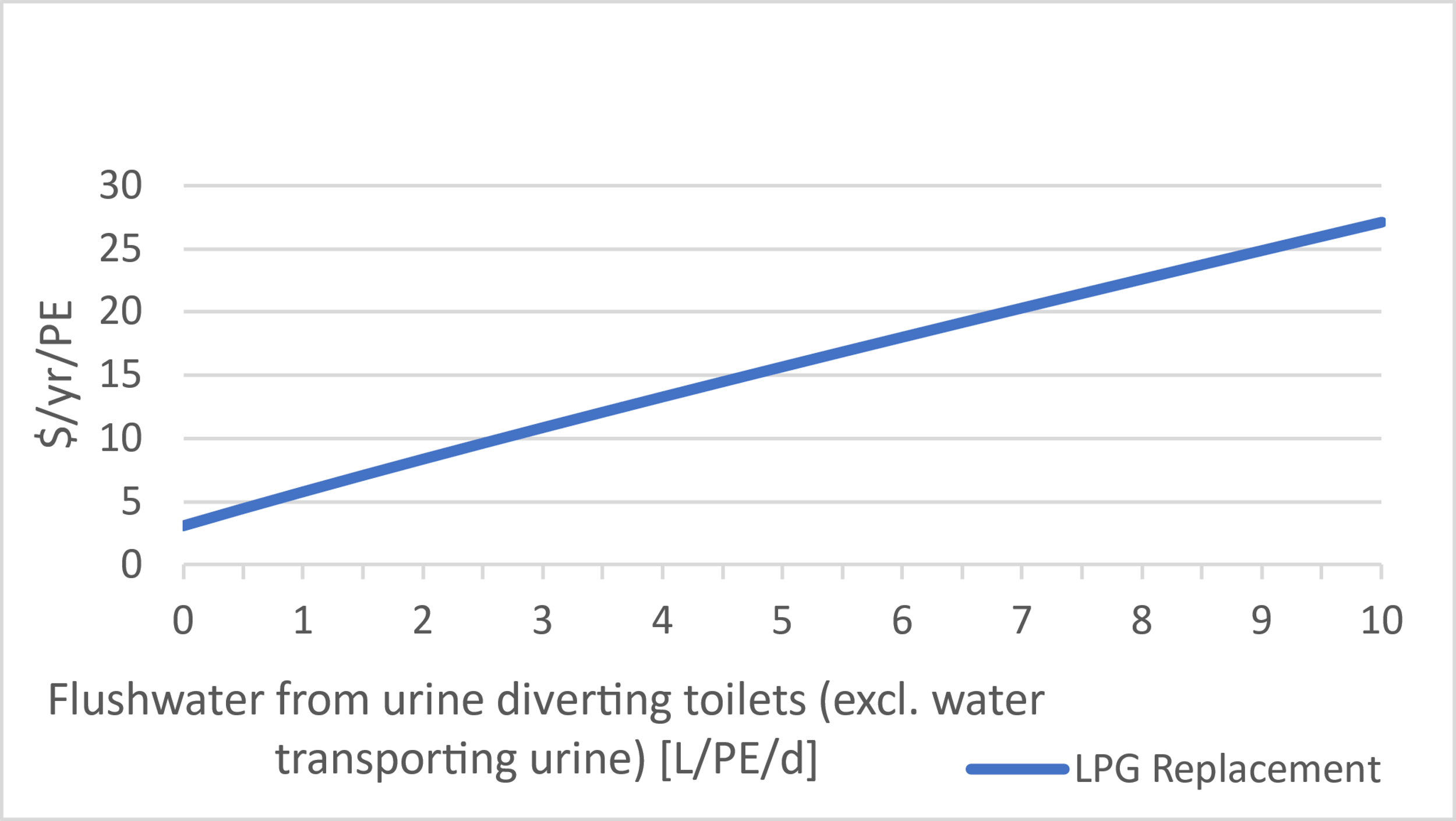

From an economic point of

view, using no flushwater via urine diverting dry toilets (UDDTs) comes

with the benefit of 24.2% lower additional capital investment needed.

However, profits from LPG replacement would be 35.7% lower. This is

because if there is very little or no water, the volume of the

compensation tank increases, compared to total digester volume. This

leads to a higher percentage of gas generated in the compensation tank

that cannot be collected and utilized. Moreover, the additional piping

would not be needed, which was accounted for in the values provided

above. Regarding GHG emissions, UDFTs could reduce additional initial

investment by 57.1%, causing the amount of saved GHG emissions compared

to system 1 to drop by 42.3%. GHG amortization time would decrease by

25.6% at the cost of an increase in economic amortization time by 15.2%,

which is illustrated in Figure 9. Spatially, UDDTs would result in 19.8%

lower additional space consumption.

From an economic point of

view, using no flushwater via urine diverting dry toilets (UDDTs) comes

with the benefit of 24.2% lower additional capital investment needed.

However, profits from LPG replacement would be 35.7% lower. This is

because if there is very little or no water, the volume of the

compensation tank increases, compared to total digester volume. This

leads to a higher percentage of gas generated in the compensation tank

that cannot be collected and utilized. Moreover, the additional piping

would not be needed, which was accounted for in the values provided

above. Regarding GHG emissions, UDFTs could reduce additional initial

investment by 57.1%, causing the amount of saved GHG emissions compared

to system 1 to drop by 42.3%. GHG amortization time would decrease by

25.6% at the cost of an increase in economic amortization time by 15.2%,

which is illustrated in Figure 9. Spatially, UDDTs would result in 19.8%

lower additional space consumption.

On the other hand, along with an increased additional space consumption of 33.8%, increasing flushwater consumption leads to more emissions, as more CH4 leaves the system dissolved. However, this effect was found to be negligible compared to the additional investment that is needed due to the over-proportional growth of the FDD compared to the Imhoff tank. UDFTs like the Laufen Save! toilet that allow toilet paper flushing after urination can have a similar flushwater consumption as SDFTs, especially at the trade center where mainly women are employed. Collecting toilet paper separately and hence saving flushwater was therefore found to reduce additional initial capital investment by 16.8% and additional initial GHG emissions by 22.8%. However, it was found that operational savings would be reduced by 5.1% economically and 7.2% regarding greenhouse gas emissions, as the ratio of compensation tank volume to total digester volume would increase. Combined, this resulted in amortization times getting reduced 12.2% and 16.7% respectively. UDFTs therefore have a flushwater consumption that is ideal with regards to amortization time, while UDDTs are most favorable towards investment costs and high flushwater consuming toilets have the most operational benefits, provided that all the water can be effectively reused.

Figures in the appendix A illustrate these findings in more detail and show how the relative influences of single parameters differ with different flushwater consumption.

Food waste dosage

As workers largely do not utilize food waste at home, it would be possible to bring household waste to the production site, increasing the amount of food waste in the digester. Dosage ratio is defined as PE of food waste per PE of wastewater producers. Assuming 1 PE of food waste can additionally be provided by the average worker and 200 workers are employed, 320 PE of food waste would be treated. This equates to a dosage ratio of 2.67, which would require an increased additional capital investment of 3.9%, an upfront GHG emission increase of 4.4%, and an additional space consumption of 2.0%. These increases can be mainly attributed to enhanced gas production and the subsequent need to enlarge the FDD, with minor contributions of the actual food waste volume added to the digester and ABR enlargement. Profit due to biogas collection would increase by 73.4%, but emissions would also increase by 30.3%. Although larger quantities of methane are emitted via the compensation tank, this is partially made up for by saved emissions from LPG replacement and from not composting. As a result, economic amortization could be reduced by 40.0% at the expense of increasing amortization time of GHG emissions by 49.9%. The net present value for 20 years after commissioning would increase from 2.7 USD PE-1 to 83.4 USD PE-1, which translates to 6730 USD. However, at the same time only 1113 kgCO2-eq PE-1 could be mitigated compared to system 1, which constitutes a reduction of 33.5%.

On the contrary, not using co-digestion would severely limit chances of project implementation because investment costs would only pay off after 33.7 years. However, GHG emissions would amortize already after 1.4 years compared to 1.6 years for a dosing ratio of 1.0, mainly due to mitigated CH4 emissions by biogas usage.

As shown in Figure 10, in

case of dosage ratios of five or more, operational GHG emissions of

system 2 are higher than for system 1. However, using Figure 11, the

combined amortization time using a carbon price of 100 USD tCO2-eq-1

stays relatively constant around 10 years, indicating that should this

carbon price come into effect in the future the dosage ratio would not

be important.

As shown in Figure 10, in

case of dosage ratios of five or more, operational GHG emissions of

system 2 are higher than for system 1. However, using Figure 11, the

combined amortization time using a carbon price of 100 USD tCO2-eq-1

stays relatively constant around 10 years, indicating that should this

carbon price come into effect in the future the dosage ratio would not

be important.

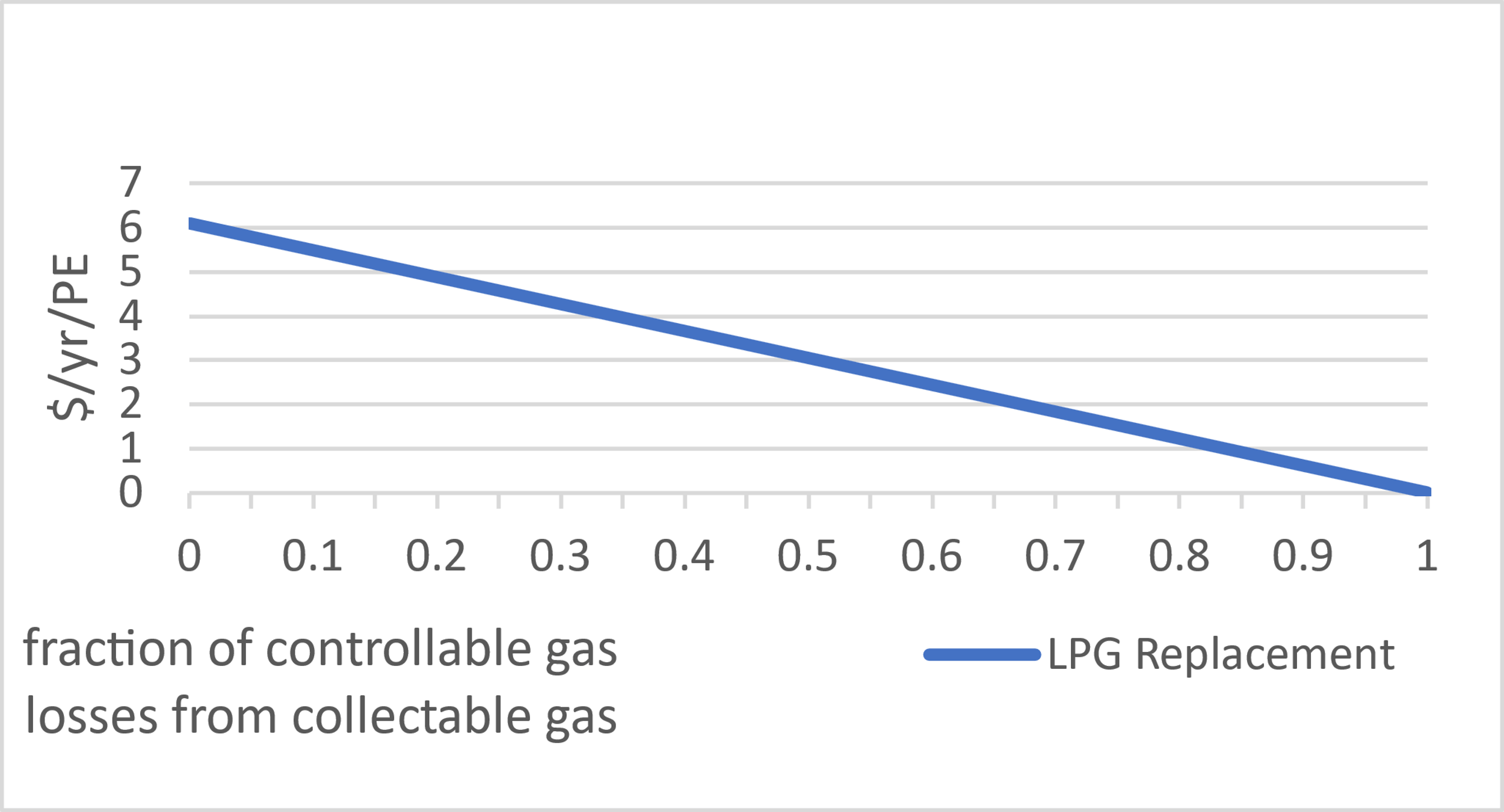

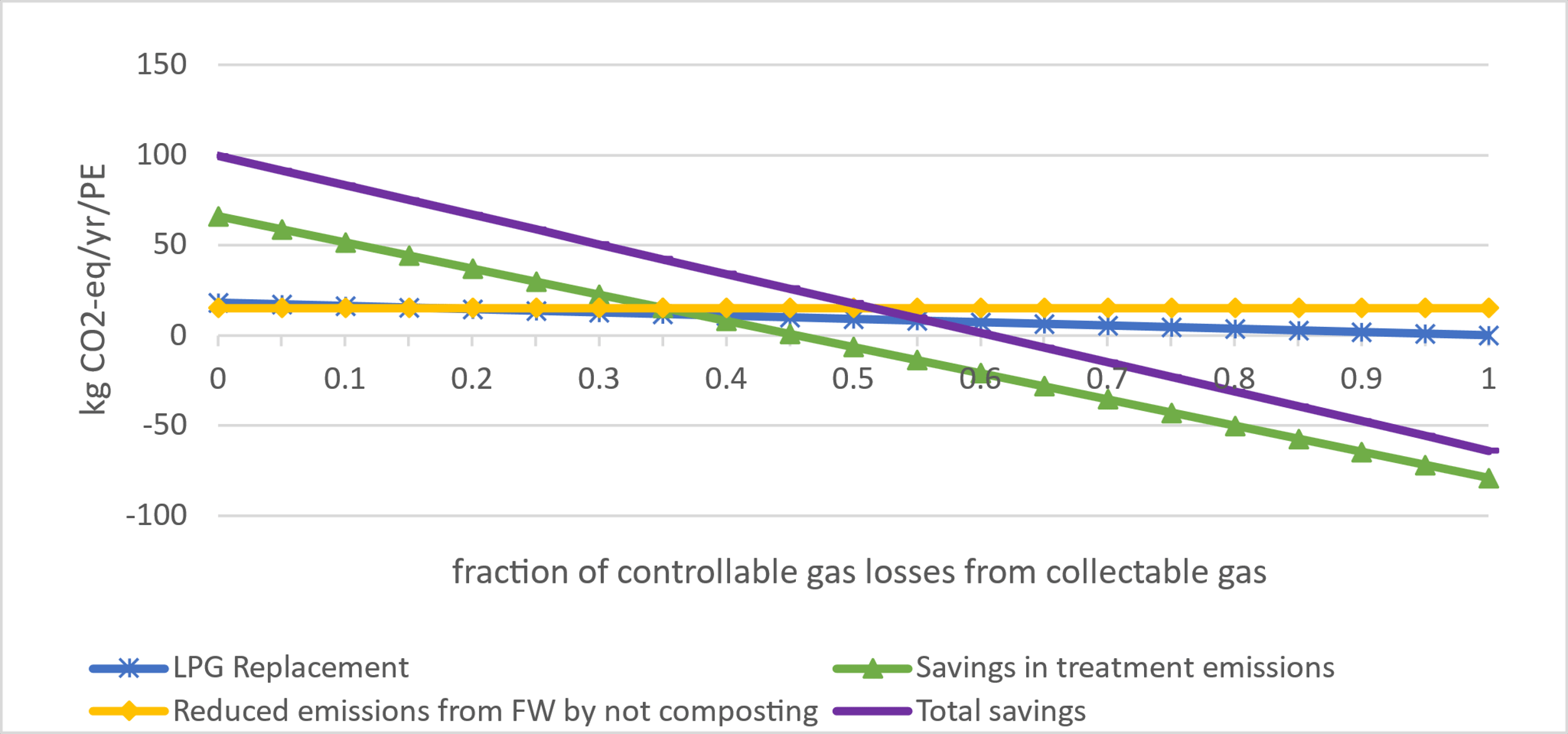

Gas losses

The fraction of collectable

gas that is not combusted and released into the atmosphere due to

leakages, lack of flaring and incomplete combustion does have a

significant impact on operational cost benefits and especially GHG

emission. A fraction of 5% was set as the default value for this

project, but digesters are known to operate across the whole spectrum in

the Global South. A maximum of 6.1 USD PE-1 can be achieved with the

value declining linearly with increasing losses. For fractions of 46% of

avoidable gas emissions, methane emissions of the FDD and ABR in system

2 outweigh those in system 1. Above 61%, net emissions from system 2 are

higher than for system 1, which is also illustrated by the amortization

time in Figure 12. In that case, additional emissions are greater than

the carbon mitigation by avoidance of LPG and composting

The fraction of collectable

gas that is not combusted and released into the atmosphere due to

leakages, lack of flaring and incomplete combustion does have a

significant impact on operational cost benefits and especially GHG

emission. A fraction of 5% was set as the default value for this

project, but digesters are known to operate across the whole spectrum in

the Global South. A maximum of 6.1 USD PE-1 can be achieved with the

value declining linearly with increasing losses. For fractions of 46% of

avoidable gas emissions, methane emissions of the FDD and ABR in system

2 outweigh those in system 1. Above 61%, net emissions from system 2 are

higher than for system 1, which is also illustrated by the amortization

time in Figure 12. In that case, additional emissions are greater than

the carbon mitigation by avoidance of LPG and composting

LPG and Carbon Price

Ghana has comparably medium to high LPG prices at around 1 USD kg-1, but price volatility is high (Asante et al. 2018, p. 98). Figures 13 and 14 show that even small changes in gas price have significant effects on economic amortization time.

Carbon pricing currently

ranges between 0 and 140 USD tCO2-eq-1 (Parry et al. 2021), however a

combination of physical and economic models by van der Ploeg and Rezai

(2021) showed that the optimal carbon price may be as high as 2.039

USD kgCO2-eq-1 if losses in productivity due to climate change impacts

are taken into account. Figure 15 shows that carbon prices as high as

this would essentially negate the high economic return periods.

Interrelations between LPG and carbon price were not investigated.

Carbon pricing currently

ranges between 0 and 140 USD tCO2-eq-1 (Parry et al. 2021), however a

combination of physical and economic models by van der Ploeg and Rezai

(2021) showed that the optimal carbon price may be as high as 2.039

USD kgCO2-eq-1 if losses in productivity due to climate change impacts

are taken into account. Figure 15 shows that carbon prices as high as

this would essentially negate the high economic return periods.

Interrelations between LPG and carbon price were not investigated.

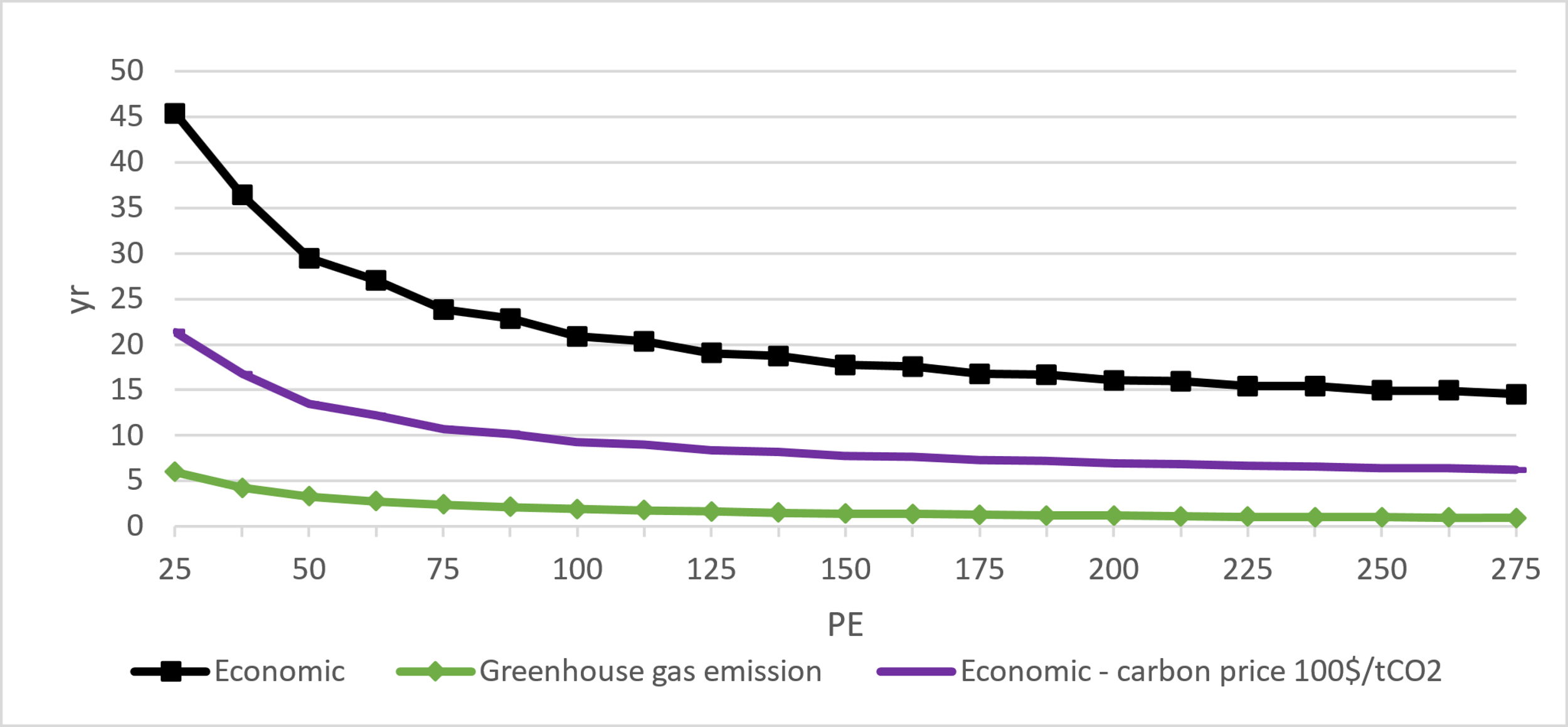

Person-equivalents

Smaller systems have to deal with higher per capita investment costs and get lower operating profits, as a higher fraction of gas is lost through the compensation tank. This is because in small systems the volume of the connector between main structure and compensation tank also plays a non-negligible role in emissions (Hamad et al. 1983). Only systems with 115 PE or more have economic amortization times of less than 20 years. However, with carbon prices of 0.1 USD kgCO2-eq-1 even systems as small as 30 PE would have 20-year amortization times. The Appendix shows the relevant figures outlining how the discussed parameters apply to systems of different sizes.

Discussion

Contributions to practice have been made towards the quantification of economic feasibility and climate impact of UDFTs in the context of FDDs as a treatment technology. A model was developed that can inform on optimal treatment selection given certain socioeconomic framework conditions like water reuse. Theoretical contributions were put forward in the form of gas emission modelling in FDDs and how this is affected by dilution.

Result validation

Recent studies regarding gas emissions from fixed dome digesters are not available. Khoiyangbam et al. (2004) measured GHG emissions from small size biogas digesters treating cattle dung and found emissions to be between 43.1 and 83.1 gCH4 m-3 d-1, corresponding to 5-8% of CH4 production. The digester for the trade center was determined to have a size of 28.8 m3 and emissions of 1.23 kgCH4 d-1, which translates to 42.7gCH4 m-3 d-1. This estimate being in the lower end would confirm model predictions of larger digesters emitting less GHGs, however comparability is limited because of the different substrates used. Hamad et al. (1983) investigated how digester pressure affects gas losses and set up a similar model that estimated the amount of slurry in the compensation tank with its subsequent emissions. Depending on digester pressure, between 5.8% and 14.5% of CH4 was lost, which is in accordance with the 8% estimated for the trade center. In this case, the digester had slightly higher pressure but its geometry was optimized to cause less emissions in the compensation tank. Empirical measurements would be needed for validation of the model. It also remains to be investigated how conditions of less-than-ideal mixing would affect results and how this could be used as a calibration parameter.

Bruun et al. (2014) did a theoretical assessment on GHG emissions from small scale fixed dome and floating drum digesters. They calculated the break-even point where the GHG benefits of replacing various fuels are set off by emissions. For LPG, they found that gas losses of 16% or more would already make biogas technology a net-emitter, which could in total lead to 1% of global emissions for an assumed maximum of 40% of gas not used. The study did however not account for external emissions that would occur if the different wastes were treated in a different way. This explains the difference to the break-even point of 61% of gas losses obtained by this thesis, which also factored in emissions from food waste composting and wastewater treatment in anaerobic systems without biogas collection but without food waste, as they emit significantly more GHGs than open defecation (Shaw et al. 2021).

Model limitations